PDF Publication Title:

Text from PDF Page: 015

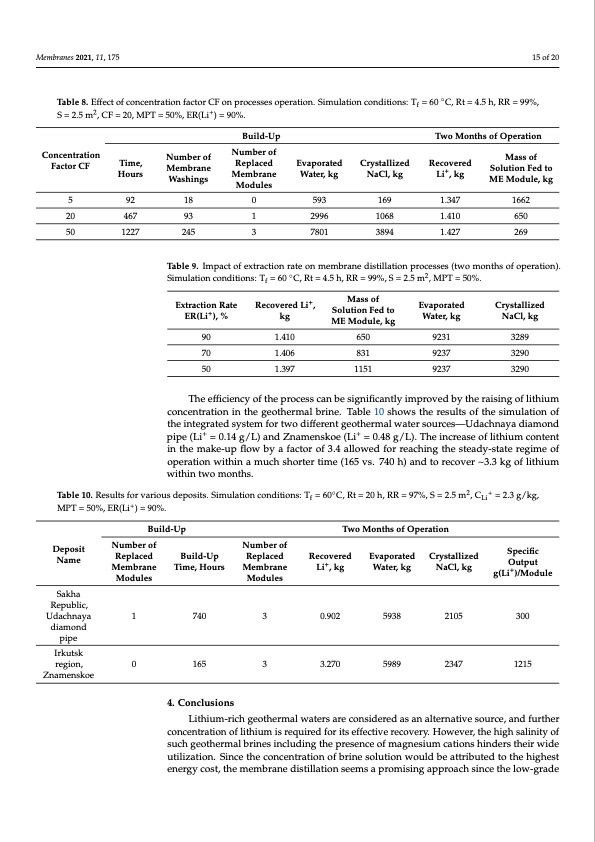

Membranes 2021, 11, 175 15 of 20 Table 8. Effect of concentration factor CF on processes operation. Simulation conditions: Tf = 60 ◦C, Rt = 4.5 h, RR = 99%, S = 2.5 m2, CF = 20, MPT = 50%, ER(Li+) = 90%. Build-Up Number of Replaced Membrane Modules Two Months of Operation Concentration Factor CF Time, Hours Number of Membrane Washings Evaporated Water, kg Crystallized NaCl, kg Recovered Li+, kg Mass of Solution Fed to ME Module, kg 5 92 18 0 593 169 1.347 1662 20 50 467 93 1 2996 1068 1.410 650 1227 245 3 7801 3894 1.427 269 Table 9. Impact of extraction rate on membrane distillation processes (two months of operation). Simulation conditions: Tf = 60 ◦C, Rt = 4.5 h, RR = 99%, S = 2.5 m2, MPT = 50%. Extraction Rate ER(Li+), % 90 70 50 Recovered Li+, kg 1.410 1.406 1.397 Mass of Solution Fed to ME Module, kg 650 831 1151 Evaporated Water, kg 9231 9237 9237 Crystallized NaCl, kg 3289 3290 3290 Deposit Name Sakha Republic, Udachnaya diamond pipe Irkutsk region, Znamenskoe Replaced Membrane Modules 1 0 Build-Up Time, Hours 740 165 4. Conclusions Number of Replaced Membrane Modules 3 3 Recovered Li+, kg 0.902 3.270 Evaporated Water, kg 5938 5989 Crystallized NaCl, kg Specific Output g(Li+ )/Module Build-Up Number of Two Months of Operation The efficiency of the process can be significantly improved by the raising of lithium concentration in the geothermal brine. Table 10 shows the results of the simulation of the integrated system for two different geothermal water sources—Udachnaya diamond pipe (Li+ = 0.14 g/L) and Znamenskoe (Li+ = 0.48 g/L). The increase of lithium content in the make-up flow by a factor of 3.4 allowed for reaching the steady-state regime of operation within a much shorter time (165 vs. 740 h) and to recover ~3.3 kg of lithium within two months. Table 10. Results for various deposits. Simulation conditions: Tf = 60◦C, Rt = 20 h, RR = 97%, S = 2.5 m2, CLi+ = 2.3 g/kg, MPT = 50%, ER(Li+) = 90%. 2105 300 2347 1215 Lithium-rich geothermal waters are considered as an alternative source, and further concentration of lithium is required for its effective recovery. However, the high salinity of such geothermal brines including the presence of magnesium cations hinders their wide utilization. Since the concentration of brine solution would be attributed to the highest energy cost, the membrane distillation seems a promising approach since the low-gradePDF Image | Process of Lithium Recovery from Geothermal Brine

PDF Search Title:

Process of Lithium Recovery from Geothermal BrineOriginal File Name Searched:

membranes-11-00175-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |