PDF Publication Title:

Text from PDF Page: 012

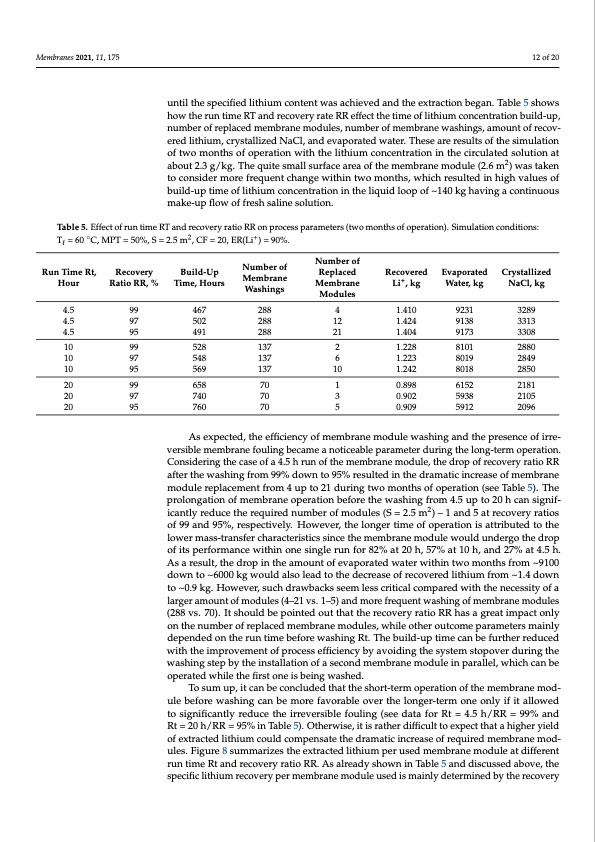

Membranes 2021, 11, 175 12 of 20 until the specified lithium content was achieved and the extraction began. Table 5 shows how the run time RT and recovery rate RR effect the time of lithium concentration build-up, number of replaced membrane modules, number of membrane washings, amount of recov- ered lithium, crystallized NaCl, and evaporated water. These are results of the simulation of two months of operation with the lithium concentration in the circulated solution at about 2.3 g/kg. The quite small surface area of the membrane module (2.6 m2) was taken to consider more frequent change within two months, which resulted in high values of build-up time of lithium concentration in the liquid loop of ~140 kg having a continuous make-up flow of fresh saline solution. Table 5. Effect of run time RT and recovery ratio RR on process parameters (two months of operation). Simulation conditions: Tf =60◦C,MPT=50%,S=2.5m2,CF=20,ER(Li+)=90%. Run Time Rt, Hour 4.5 4.5 4.5 10 10 10 20 20 20 Recovery Ratio RR, % 99 97 95 99 97 95 99 97 95 Build-Up Time, Hours 467 502 491 528 548 569 658 740 760 Number of Membrane Washings 288 288 288 137 137 137 Number of Replaced Membrane Modules 4 12 21 2 6 10 Recovered Li+, kg 1.410 1.424 1.404 1.228 1.223 1.242 0.898 0.902 0.909 Evaporated Water, kg 9231 9138 9173 8101 8019 8018 6152 5938 5912 Crystallized NaCl, kg 3289 3313 3308 2880 2849 2850 2181 2105 2096 70 1 70 3 70 5 As expected, the efficiency of membrane module washing and the presence of irre- versible membrane fouling became a noticeable parameter during the long-term operation. Considering the case of a 4.5 h run of the membrane module, the drop of recovery ratio RR after the washing from 99% down to 95% resulted in the dramatic increase of membrane module replacement from 4 up to 21 during two months of operation (see Table 5). The prolongation of membrane operation before the washing from 4.5 up to 20 h can signif- icantly reduce the required number of modules (S = 2.5 m2) – 1 and 5 at recovery ratios of 99 and 95%, respectively. However, the longer time of operation is attributed to the lower mass-transfer characteristics since the membrane module would undergo the drop of its performance within one single run for 82% at 20 h, 57% at 10 h, and 27% at 4.5 h. As a result, the drop in the amount of evaporated water within two months from ~9100 down to ~6000 kg would also lead to the decrease of recovered lithium from ~1.4 down to ~0.9 kg. However, such drawbacks seem less critical compared with the necessity of a larger amount of modules (4–21 vs. 1–5) and more frequent washing of membrane modules (288 vs. 70). It should be pointed out that the recovery ratio RR has a great impact only on the number of replaced membrane modules, while other outcome parameters mainly depended on the run time before washing Rt. The build-up time can be further reduced with the improvement of process efficiency by avoiding the system stopover during the washing step by the installation of a second membrane module in parallel, which can be operated while the first one is being washed. To sum up, it can be concluded that the short-term operation of the membrane mod- ule before washing can be more favorable over the longer-term one only if it allowed to significantly reduce the irreversible fouling (see data for Rt = 4.5 h/RR = 99% and Rt = 20 h/RR = 95% in Table 5). Otherwise, it is rather difficult to expect that a higher yield of extracted lithium could compensate the dramatic increase of required membrane mod- ules. Figure 8 summarizes the extracted lithium per used membrane module at different run time Rt and recovery ratio RR. As already shown in Table 5 and discussed above, the specific lithium recovery per membrane module used is mainly determined by the recoveryPDF Image | Process of Lithium Recovery from Geothermal Brine

PDF Search Title:

Process of Lithium Recovery from Geothermal BrineOriginal File Name Searched:

membranes-11-00175-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |