PDF Publication Title:

Text from PDF Page: 035

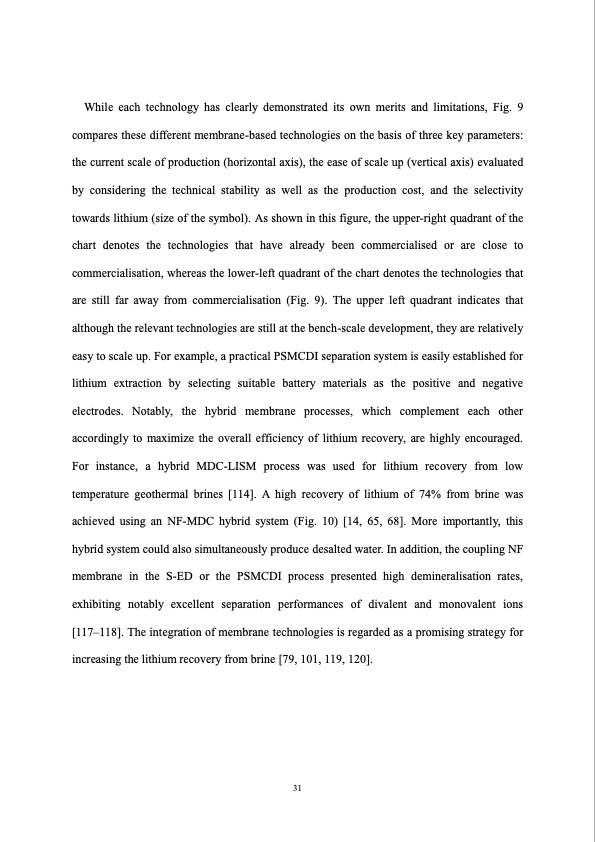

While each technology has clearly demonstrated its own merits and limitations, Fig. 9 compares these different membrane-based technologies on the basis of three key parameters: the current scale of production (horizontal axis), the ease of scale up (vertical axis) evaluated by considering the technical stability as well as the production cost, and the selectivity towards lithium (size of the symbol). As shown in this figure, the upper-right quadrant of the chart denotes the technologies that have already been commercialised or are close to commercialisation, whereas the lower-left quadrant of the chart denotes the technologies that are still far away from commercialisation (Fig. 9). The upper left quadrant indicates that although the relevant technologies are still at the bench-scale development, they are relatively easy to scale up. For example, a practical PSMCDI separation system is easily established for lithium extraction by selecting suitable battery materials as the positive and negative electrodes. Notably, the hybrid membrane processes, which complement each other accordingly to maximize the overall efficiency of lithium recovery, are highly encouraged. For instance, a hybrid MDC-LISM process was used for lithium recovery from low temperature geothermal brines [114]. A high recovery of lithium of 74% from brine was achieved using an NF-MDC hybrid system (Fig. 10) [14, 65, 68]. More importantly, this hybrid system could also simultaneously produce desalted water. In addition, the coupling NF membrane in the S-ED or the PSMCDI process presented high demineralisation rates, exhibiting notably excellent separation performances of divalent and monovalent ions [117–118]. The integration of membrane technologies is regarded as a promising strategy for increasing the lithium recovery from brine [79, 101, 119, 120]. 31PDF Image | Membrane based technologies for lithium recovery from water lithium

PDF Search Title:

Membrane based technologies for lithium recovery from water lithiumOriginal File Name Searched:

Content.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |