PDF Publication Title:

Text from PDF Page: 021

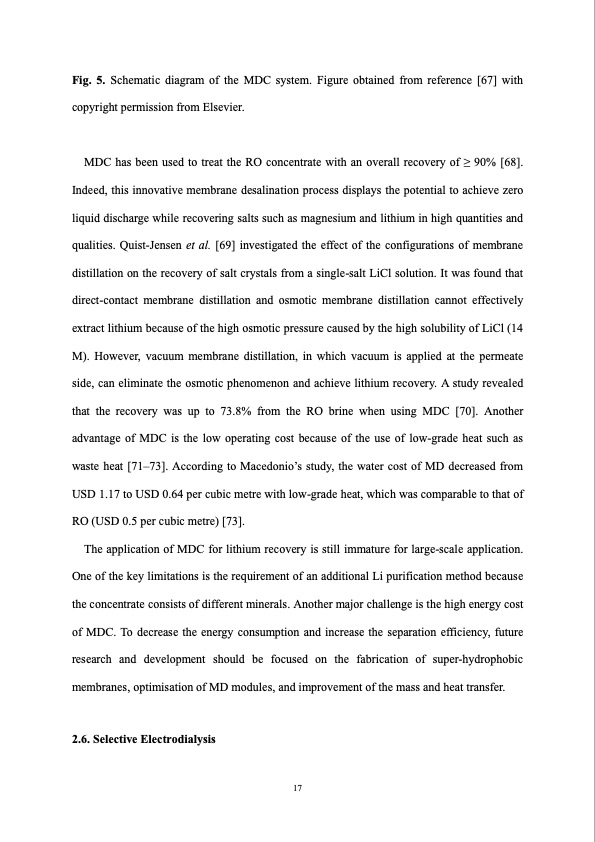

Fig. 5. Schematic diagram of the MDC system. Figure obtained from reference [67] with copyright permission from Elsevier. MDC has been used to treat the RO concentrate with an overall recovery of ≥ 90% [68]. Indeed, this innovative membrane desalination process displays the potential to achieve zero liquid discharge while recovering salts such as magnesium and lithium in high quantities and qualities. Quist-Jensen et al. [69] investigated the effect of the configurations of membrane distillation on the recovery of salt crystals from a single-salt LiCl solution. It was found that direct-contact membrane distillation and osmotic membrane distillation cannot effectively extract lithium because of the high osmotic pressure caused by the high solubility of LiCl (14 M). However, vacuum membrane distillation, in which vacuum is applied at the permeate side, can eliminate the osmotic phenomenon and achieve lithium recovery. A study revealed that the recovery was up to 73.8% from the RO brine when using MDC [70]. Another advantage of MDC is the low operating cost because of the use of low-grade heat such as waste heat [71–73]. According to Macedonio’s study, the water cost of MD decreased from USD 1.17 to USD 0.64 per cubic metre with low-grade heat, which was comparable to that of RO (USD 0.5 per cubic metre) [73]. The application of MDC for lithium recovery is still immature for large-scale application. One of the key limitations is the requirement of an additional Li purification method because the concentrate consists of different minerals. Another major challenge is the high energy cost of MDC. To decrease the energy consumption and increase the separation efficiency, future research and development should be focused on the fabrication of super-hydrophobic membranes, optimisation of MD modules, and improvement of the mass and heat transfer. 2.6. Selective Electrodialysis 17PDF Image | Membrane based technologies for lithium recovery from water lithium

PDF Search Title:

Membrane based technologies for lithium recovery from water lithiumOriginal File Name Searched:

Content.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |