PDF Publication Title:

Text from PDF Page: 017

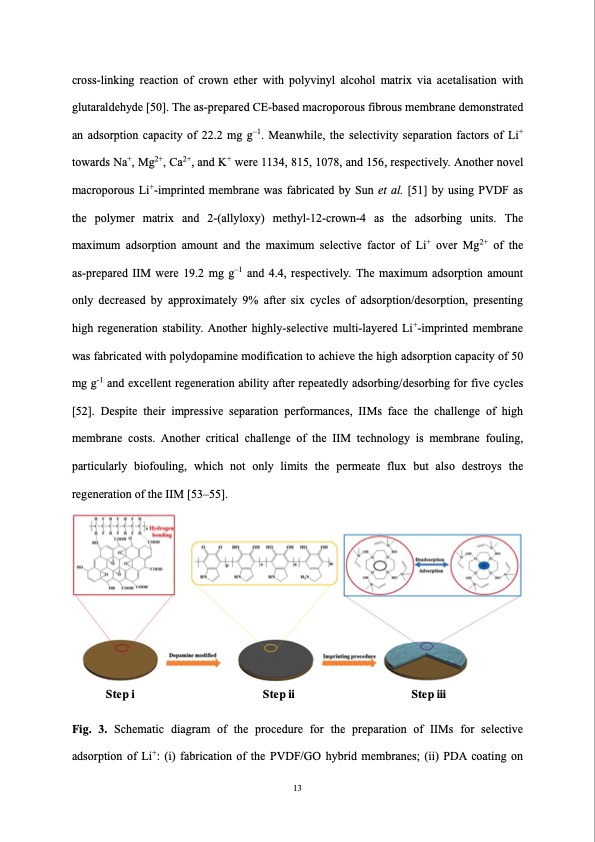

cross-linking reaction of crown ether with polyvinyl alcohol matrix via acetalisation with glutaraldehyde [50]. The as-prepared CE-based macroporous fibrous membrane demonstrated an adsorption capacity of 22.2 mg g–1. Meanwhile, the selectivity separation factors of Li+ towards Na+, Mg2+, Ca2+, and K+ were 1134, 815, 1078, and 156, respectively. Another novel macroporous Li+-imprinted membrane was fabricated by Sun et al. [51] by using PVDF as the polymer matrix and 2-(allyloxy) methyl-12-crown-4 as the adsorbing units. The maximum adsorption amount and the maximum selective factor of Li+ over Mg2+ of the as-prepared IIM were 19.2 mg g–1 and 4.4, respectively. The maximum adsorption amount only decreased by approximately 9% after six cycles of adsorption/desorption, presenting high regeneration stability. Another highly-selective multi-layered Li+-imprinted membrane was fabricated with polydopamine modification to achieve the high adsorption capacity of 50 mg g-1 and excellent regeneration ability after repeatedly adsorbing/desorbing for five cycles [52]. Despite their impressive separation performances, IIMs face the challenge of high membrane costs. Another critical challenge of the IIM technology is membrane fouling, particularly biofouling, which not only limits the permeate flux but also destroys the regeneration of the IIM [53–55]. Step i Step ii Step iii Fig. 3. Schematic diagram of the procedure for the preparation of IIMs for selective adsorption of Li+: (i) fabrication of the PVDF/GO hybrid membranes; (ii) PDA coating on 13PDF Image | Membrane based technologies for lithium recovery from water lithium

PDF Search Title:

Membrane based technologies for lithium recovery from water lithiumOriginal File Name Searched:

Content.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |