PDF Publication Title:

Text from PDF Page: 019

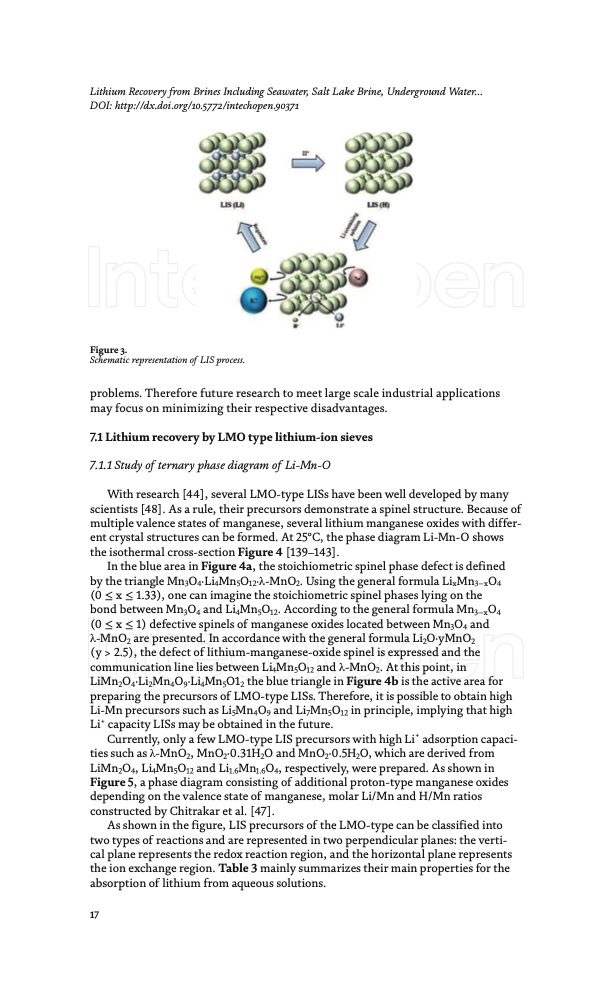

Lithium Recovery from Brines Including Seawater, Salt Lake Brine, Underground Water... DOI: http://dx.doi.org/10.5772/intechopen.90371 Figure 3. Schematic representation of LIS process. problems. Therefore future research to meet large scale industrial applications may focus on minimizing their respective disadvantages. 7.1 Lithium recovery by LMO type lithium-ion sieves 7.1.1 Study of ternary phase diagram of Li-Mn-O With research [44], several LMO-type LISs have been well developed by many scientists [48]. As a rule, their precursors demonstrate a spinel structure. Because of multiple valence states of manganese, several lithium manganese oxides with differ- ent crystal structures can be formed. At 25°C, the phase diagram Li-Mn-O shows the isothermal cross-section Figure 4 [139–143]. In the blue area in Figure 4a, the stoichiometric spinel phase defect is defined by the triangle Mn3O4·Li4Mn5O12·λ-MnO2. Using the general formula LixMn3−xO4 (0 ≤ x ≤ 1.33), one can imagine the stoichiometric spinel phases lying on the bond between Mn3O4 and Li4Mn5O12. According to the general formula Mn3−xO4 (0 ≤ x ≤ 1) defective spinels of manganese oxides located between Mn3O4 and λ-MnO2 are presented. In accordance with the general formula Li2O·yMnO2 (y > 2.5), the defect of lithium-manganese-oxide spinel is expressed and the communication line lies between Li4Mn5O12 and λ-MnO2. At this point, in LiMn2O4·Li2Mn4O9·Li4Mn5O12 the blue triangle in Figure 4b is the active area for preparing the precursors of LMO-type LISs. Therefore, it is possible to obtain high Li-Mn precursors such as Li5Mn4O9 and Li7Mn5O12 in principle, implying that high Li+ capacity LISs may be obtained in the future. Currently, only a few LMO-type LIS precursors with high Li+ adsorption capaci- ties such as λ-MnO2, MnO2·0.31H2O and MnO2·0.5H2O, which are derived from LiMn2O4, Li4Mn5O12 and Li1.6Mn1.6O4, respectively, were prepared. As shown in Figure 5, a phase diagram consisting of additional proton-type manganese oxides depending on the valence state of manganese, molar Li/Mn and H/Mn ratios constructed by Chitrakar et al. [47]. As shown in the figure, LIS precursors of the LMO-type can be classified into two types of reactions and are represented in two perpendicular planes: the verti- cal plane represents the redox reaction region, and the horizontal plane represents the ion exchange region. Table 3 mainly summarizes their main properties for the absorption of lithium from aqueous solutions. 17PDF Image | Lithium Recovery from Seawater Salt Lake Brine

PDF Search Title:

Lithium Recovery from Seawater Salt Lake BrineOriginal File Name Searched:

IntechOpenSamadiyBookchapter.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |