PDF Publication Title:

Text from PDF Page: 019

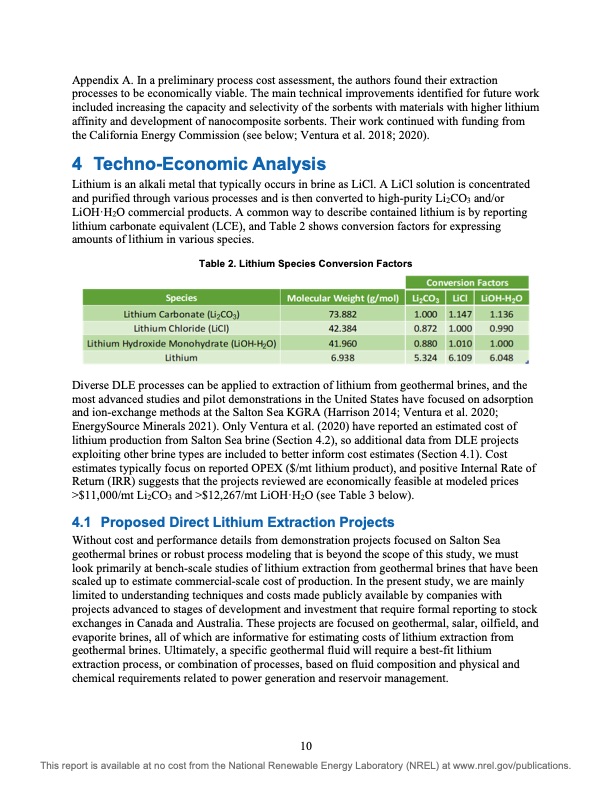

Appendix A. In a preliminary process cost assessment, the authors found their extraction processes to be economically viable. The main technical improvements identified for future work included increasing the capacity and selectivity of the sorbents with materials with higher lithium affinity and development of nanocomposite sorbents. Their work continued with funding from the California Energy Commission (see below; Ventura et al. 2018; 2020). 4 Techno-EconomicAnalysis Lithium is an alkali metal that typically occurs in brine as LiCl. A LiCl solution is concentrated and purified through various processes and is then converted to high-purity Li2CO3 and/or LiOH·H2O commercial products. A common way to describe contained lithium is by reporting lithium carbonate equivalent (LCE), and Table 2 shows conversion factors for expressing amounts of lithium in various species. Table 2. Lithium Species Conversion Factors Diverse DLE processes can be applied to extraction of lithium from geothermal brines, and the most advanced studies and pilot demonstrations in the United States have focused on adsorption and ion-exchange methods at the Salton Sea KGRA (Harrison 2014; Ventura et al. 2020; EnergySource Minerals 2021). Only Ventura et al. (2020) have reported an estimated cost of lithium production from Salton Sea brine (Section 4.2), so additional data from DLE projects exploiting other brine types are included to better inform cost estimates (Section 4.1). Cost estimates typically focus on reported OPEX ($/mt lithium product), and positive Internal Rate of Return (IRR) suggests that the projects reviewed are economically feasible at modeled prices >$11,000/mt Li2CO3 and >$12,267/mt LiOH·H2O (see Table 3 below). 4.1 ProposedDirectLithiumExtractionProjects Without cost and performance details from demonstration projects focused on Salton Sea geothermal brines or robust process modeling that is beyond the scope of this study, we must look primarily at bench-scale studies of lithium extraction from geothermal brines that have been scaled up to estimate commercial-scale cost of production. In the present study, we are mainly limited to understanding techniques and costs made publicly available by companies with projects advanced to stages of development and investment that require formal reporting to stock exchanges in Canada and Australia. These projects are focused on geothermal, salar, oilfield, and evaporite brines, all of which are informative for estimating costs of lithium extraction from geothermal brines. Ultimately, a specific geothermal fluid will require a best-fit lithium extraction process, or combination of processes, based on fluid composition and physical and chemical requirements related to power generation and reservoir management. 10 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |