PDF Publication Title:

Text from PDF Page: 092

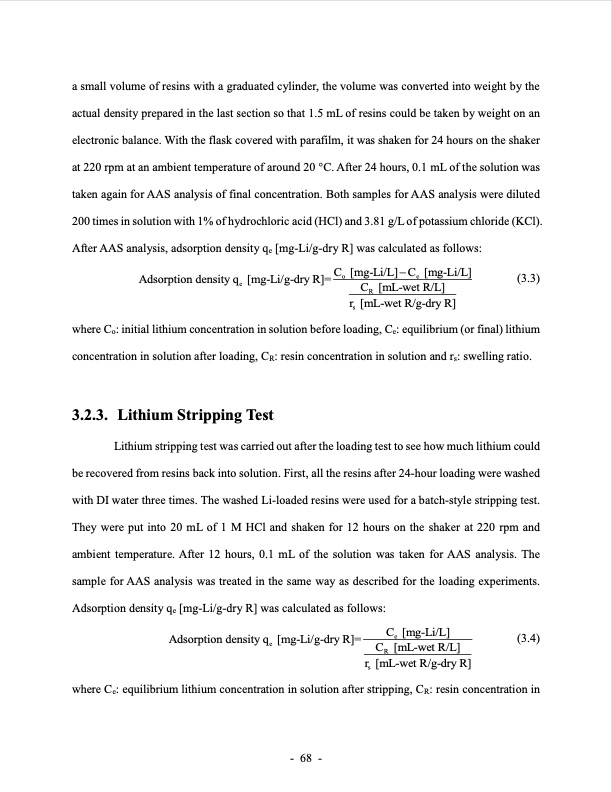

a small volume of resins with a graduated cylinder, the volume was converted into weight by the actual density prepared in the last section so that 1.5 mL of resins could be taken by weight on an electronic balance. With the flask covered with parafilm, it was shaken for 24 hours on the shaker at 220 rpm at an ambient temperature of around 20 °C. After 24 hours, 0.1 mL of the solution was taken again for AAS analysis of final concentration. Both samples for AAS analysis were diluted 200 times in solution with 1% of hydrochloric acid (HCl) and 3.81 g/L of potassium chloride (KCl). After AAS analysis, adsorption density qe [mg-Li/g-dry R] was calculated as follows: (3.3) where Co: initial lithium concentration in solution before loading, Ce: equilibrium (or final) lithium concentration in solution after loading, CR: resin concentration in solution and rs: swelling ratio. 3.2.3. LithiumStrippingTest Lithium stripping test was carried out after the loading test to see how much lithium could be recovered from resins back into solution. First, all the resins after 24-hour loading were washed with DI water three times. The washed Li-loaded resins were used for a batch-style stripping test. They were put into 20 mL of 1 M HCl and shaken for 12 hours on the shaker at 220 rpm and ambient temperature. After 12 hours, 0.1 mL of the solution was taken for AAS analysis. The sample for AAS analysis was treated in the same way as described for the loading experiments. Adsorption density qe [mg-Li/g-dry R] was calculated as follows: (3.4) where Ce: equilibrium lithium concentration in solution after stripping, CR: resin concentration in Adsorption density q e [mg-Li/g-dry R]= Co [mg-Li/L] − Ce [mg-Li/L] CR [mL-wet R/L] rs [mL-wet R/g-dry R] Adsorption density qe [mg-Li/g-dry R]= Ce [mg-Li/L] CR [mL-wet R/L] rs [mL-wet R/g-dry R] - 68 -PDF Image | LITHIUM EXTRACTION FROM BRINE using ion resin

PDF Search Title:

LITHIUM EXTRACTION FROM BRINE using ion resinOriginal File Name Searched:

3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |