PDF Publication Title:

Text from PDF Page: 071

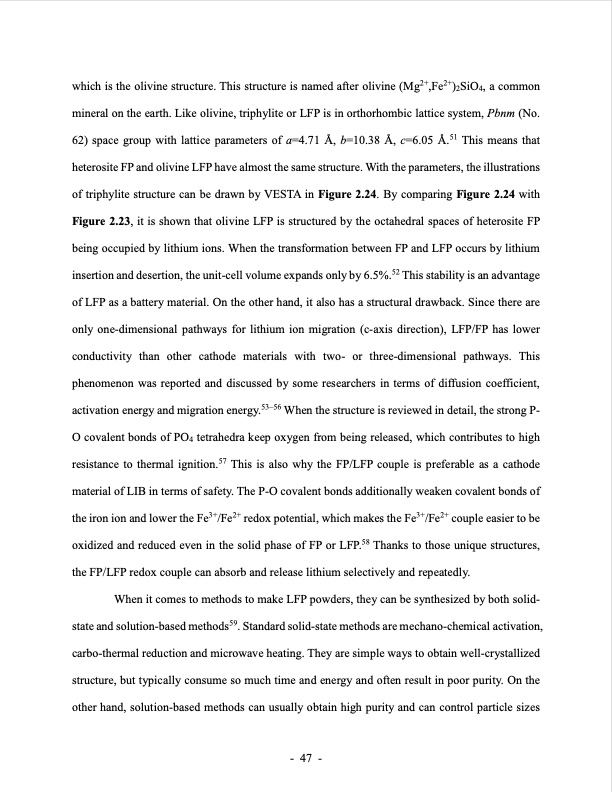

which is the olivine structure. This structure is named after olivine (Mg2+,Fe2+)2SiO4, a common mineral on the earth. Like olivine, triphylite or LFP is in orthorhombic lattice system, Pbnm (No. 62) space group with lattice parameters of a=4.71 Å, b=10.38 Å, c=6.05 Å.51 This means that heterosite FP and olivine LFP have almost the same structure. With the parameters, the illustrations of triphylite structure can be drawn by VESTA in Figure 2.24. By comparing Figure 2.24 with Figure 2.23, it is shown that olivine LFP is structured by the octahedral spaces of heterosite FP being occupied by lithium ions. When the transformation between FP and LFP occurs by lithium insertion and desertion, the unit-cell volume expands only by 6.5%.52 This stability is an advantage of LFP as a battery material. On the other hand, it also has a structural drawback. Since there are only one-dimensional pathways for lithium ion migration (c-axis direction), LFP/FP has lower conductivity than other cathode materials with two- or three-dimensional pathways. This phenomenon was reported and discussed by some researchers in terms of diffusion coefficient, activation energy and migration energy.53–56 When the structure is reviewed in detail, the strong P- O covalent bonds of PO4 tetrahedra keep oxygen from being released, which contributes to high resistance to thermal ignition.57 This is also why the FP/LFP couple is preferable as a cathode material of LIB in terms of safety. The P-O covalent bonds additionally weaken covalent bonds of the iron ion and lower the Fe3+/Fe2+ redox potential, which makes the Fe3+/Fe2+ couple easier to be oxidized and reduced even in the solid phase of FP or LFP.58 Thanks to those unique structures, the FP/LFP redox couple can absorb and release lithium selectively and repeatedly. When it comes to methods to make LFP powders, they can be synthesized by both solid- state and solution-based methods59. Standard solid-state methods are mechano-chemical activation, carbo-thermal reduction and microwave heating. They are simple ways to obtain well-crystallized structure, but typically consume so much time and energy and often result in poor purity. On the other hand, solution-based methods can usually obtain high purity and can control particle sizes - 47 -PDF Image | LITHIUM EXTRACTION FROM BRINE using ion resin

PDF Search Title:

LITHIUM EXTRACTION FROM BRINE using ion resinOriginal File Name Searched:

3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |