PDF Publication Title:

Text from PDF Page: 002

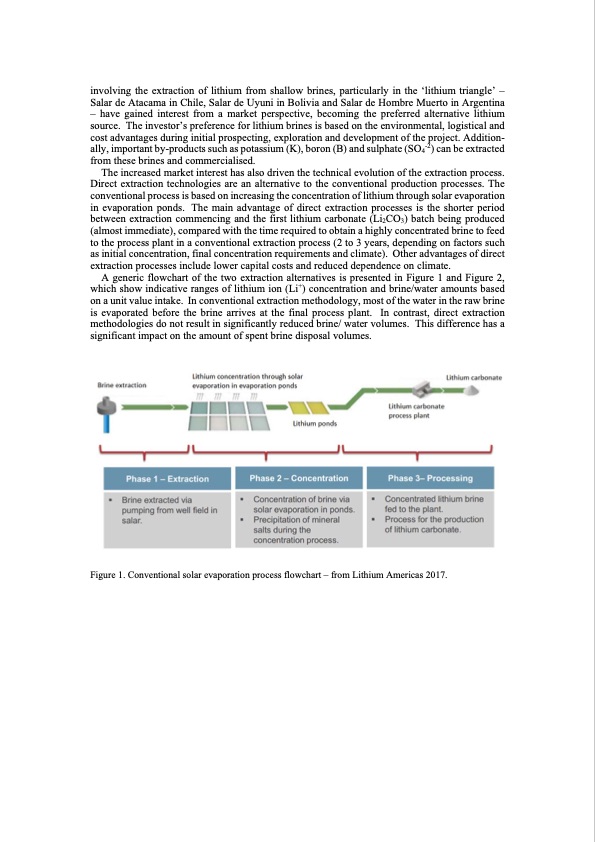

involving the extraction of lithium from shallow brines, particularly in the ‘lithium triangle’ – Salar de Atacama in Chile, Salar de Uyuni in Bolivia and Salar de Hombre Muerto in Argentina – have gained interest from a market perspective, becoming the preferred alternative lithium source. The investor’s preference for lithium brines is based on the environmental, logistical and cost advantages during initial prospecting, exploration and development of the project. Addition- ally, important by-products such as potassium (K), boron (B) and sulphate (SO4-2) can be extracted from these brines and commercialised. The increased market interest has also driven the technical evolution of the extraction process. Direct extraction technologies are an alternative to the conventional production processes. The conventional process is based on increasing the concentration of lithium through solar evaporation in evaporation ponds. The main advantage of direct extraction processes is the shorter period between extraction commencing and the first lithium carbonate (Li2CO3) batch being produced (almost immediate), compared with the time required to obtain a highly concentrated brine to feed to the process plant in a conventional extraction process (2 to 3 years, depending on factors such as initial concentration, final concentration requirements and climate). Other advantages of direct extraction processes include lower capital costs and reduced dependence on climate. A generic flowchart of the two extraction alternatives is presented in Figure 1 and Figure 2, which show indicative ranges of lithium ion (Li+) concentration and brine/water amounts based on a unit value intake. In conventional extraction methodology, most of the water in the raw brine is evaporated before the brine arrives at the final process plant. In contrast, direct extraction methodologies do not result in significantly reduced brine/ water volumes. This difference has a significant impact on the amount of spent brine disposal volumes. Figure 1. Conventional solar evaporation process flowchart – from Lithium Americas 2017.PDF Image | Direct extraction lithium processes

PDF Search Title:

Direct extraction lithium processesOriginal File Name Searched:

Ezama-Hoyos-Cortegoso-Braun-Spent_Brine_Disposal-TMW_Paper20191128190251287.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |