PDF Publication Title:

Text from PDF Page: 005

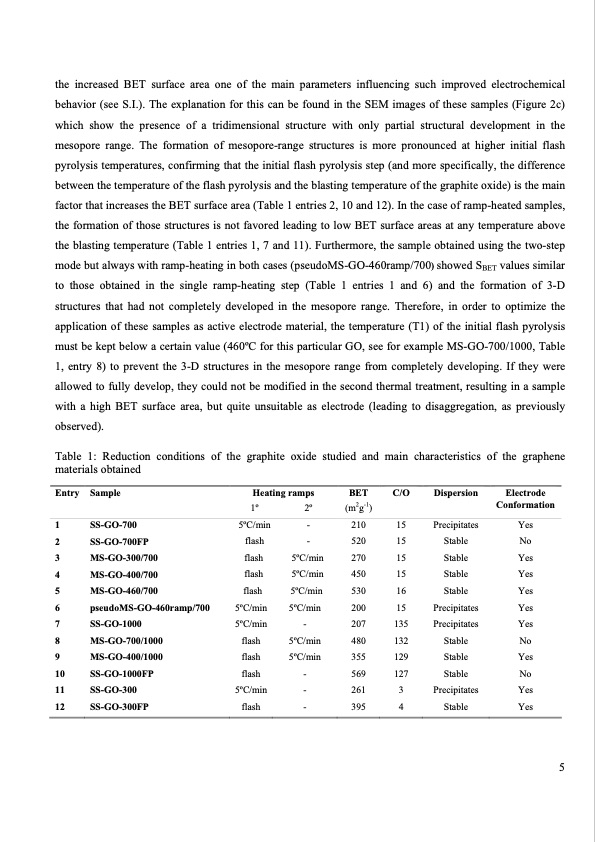

the increased BET surface area one of the main parameters influencing such improved electrochemical behavior (see S.I.). The explanation for this can be found in the SEM images of these samples (Figure 2c) which show the presence of a tridimensional structure with only partial structural development in the mesopore range. The formation of mesopore-range structures is more pronounced at higher initial flash pyrolysis temperatures, confirming that the initial flash pyrolysis step (and more specifically, the difference between the temperature of the flash pyrolysis and the blasting temperature of the graphite oxide) is the main factor that increases the BET surface area (Table 1 entries 2, 10 and 12). In the case of ramp-heated samples, the formation of those structures is not favored leading to low BET surface areas at any temperature above the blasting temperature (Table 1 entries 1, 7 and 11). Furthermore, the sample obtained using the two-step mode but always with ramp-heating in both cases (pseudoMS-GO-460ramp/700) showed SBET values similar to those obtained in the single ramp-heating step (Table 1 entries 1 and 6) and the formation of 3-D structures that had not completely developed in the mesopore range. Therefore, in order to optimize the application of these samples as active electrode material, the temperature (T1) of the initial flash pyrolysis must be kept below a certain value (460oC for this particular GO, see for example MS-GO-700/1000, Table 1, entry 8) to prevent the 3-D structures in the mesopore range from completely developing. If they were allowed to fully develop, they could not be modified in the second thermal treatment, resulting in a sample with a high BET surface area, but quite unsuitable as electrode (leading to disaggregation, as previously observed). Table 1: Reduction conditions of the graphite oxide studied and main characteristics of the graphene materials obtained Entry Sample Heating ramps BET 1o 2o (m2g-1) C/O Conformation 1 SS-GO-700 5oC/min - 210 15 SS-GO-700FP MS-GO-300/700 MS-GO-400/700 MS-GO-460/700 pseudoMS-GO-460ramp/700 SS-GO-1000 MS-GO-700/1000 MS-GO-400/1000 SS-GO-1000FP SS-GO-300 SS-GO-300FP Dispersion Electrode 2 3 4 5 6 7 5oC/min flash flash Stable No Stable Yes Stable Yes Stable Yes 8 9 10 flash - 11 5oC/min - 12 flash - Stable No Stable Yes Stable No flash flash flash - 5oC/min 5oC/min 520 15 270 15 450 15 530 16 200 15 207 135 Precipitates Yes flash 5oC/min 5oC/min 5oC/min - 5oC/min 5oC/min Precipitates Yes Precipitates Yes 480 132 355 129 569 127 261 3 Precipitates Yes 395 4 Stable Yes 5PDF Image | TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESS

PDF Search Title:

TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESSOriginal File Name Searched:

36194253.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)