PDF Publication Title:

Text from PDF Page: 003

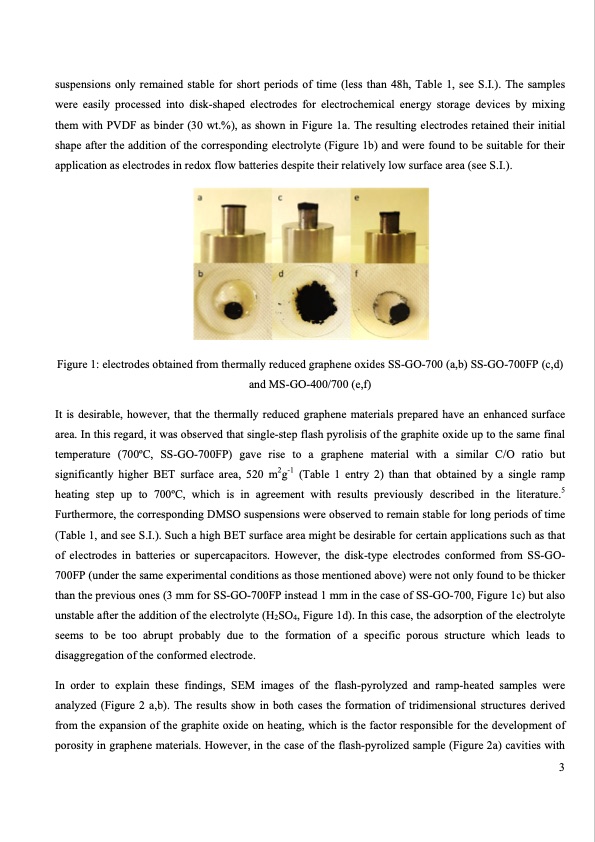

suspensions only remained stable for short periods of time (less than 48h, Table 1, see S.I.). The samples were easily processed into disk-shaped electrodes for electrochemical energy storage devices by mixing them with PVDF as binder (30 wt.%), as shown in Figure 1a. The resulting electrodes retained their initial shape after the addition of the corresponding electrolyte (Figure 1b) and were found to be suitable for their application as electrodes in redox flow batteries despite their relatively low surface area (see S.I.). Figure 1: electrodes obtained from thermally reduced graphene oxides SS-GO-700 (a,b) SS-GO-700FP (c,d) and MS-GO-400/700 (e,f) It is desirable, however, that the thermally reduced graphene materials prepared have an enhanced surface area. In this regard, it was observed that single-step flash pyrolisis of the graphite oxide up to the same final temperature (700oC, SS-GO-700FP) gave rise to a graphene material with a similar C/O ratio but significantly higher BET surface area, 520 m2g-1 (Table 1 entry 2) than that obtained by a single ramp heating step up to 700oC, which is in agreement with results previously described in the literature.5 Furthermore, the corresponding DMSO suspensions were observed to remain stable for long periods of time (Table 1, and see S.I.). Such a high BET surface area might be desirable for certain applications such as that of electrodes in batteries or supercapacitors. However, the disk-type electrodes conformed from SS-GO- 700FP (under the same experimental conditions as those mentioned above) were not only found to be thicker than the previous ones (3 mm for SS-GO-700FP instead 1 mm in the case of SS-GO-700, Figure 1c) but also unstable after the addition of the electrolyte (H2SO4, Figure 1d). In this case, the adsorption of the electrolyte seems to be too abrupt probably due to the formation of a specific porous structure which leads to disaggregation of the conformed electrode. In order to explain these findings, SEM images of the flash-pyrolyzed and ramp-heated samples were analyzed (Figure 2 a,b). The results show in both cases the formation of tridimensional structures derived from the expansion of the graphite oxide on heating, which is the factor responsible for the development of porosity in graphene materials. However, in the case of the flash-pyrolized sample (Figure 2a) cavities with 3PDF Image | TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESS

PDF Search Title:

TUNING GRAPHENE MULTI-STEP THERMAL REDUCTION PROCESSOriginal File Name Searched:

36194253.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |