PDF Publication Title:

Text from PDF Page: 008

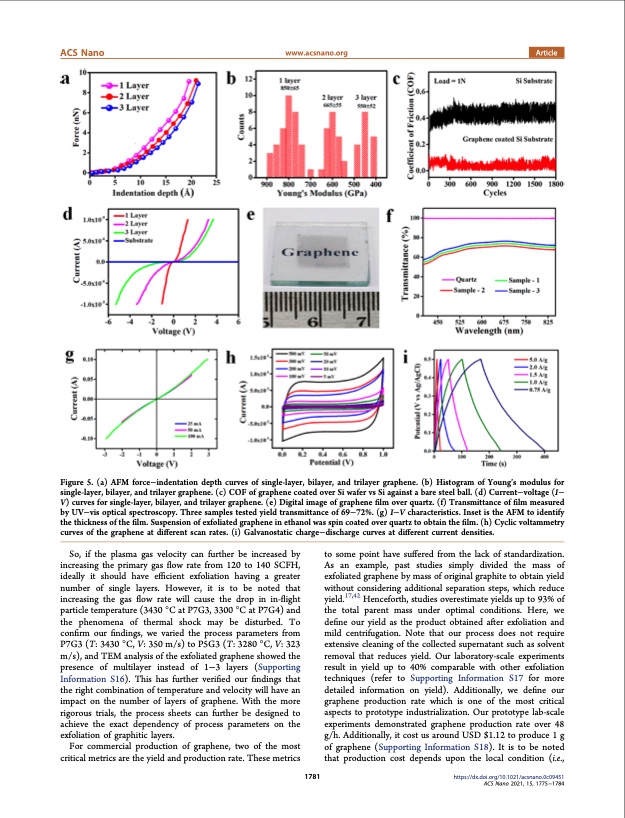

ACS Nano www.acsnano.org Article Figure 5. (a) AFM force−indentation depth curves of single-layer, bilayer, and trilayer graphene. (b) Histogram of Young’s modulus for single-layer, bilayer, and trilayer graphene. (c) COF of graphene coated over Si wafer vs Si against a bare steel ball. (d) Current−voltage (I− V) curves for single-layer, bilayer, and trilayer graphene. (e) Digital image of graphene film over quartz. (f) Transmittance of film measured by UV−vis optical spectroscopy. Three samples tested yield transmittance of 69−72%. (g) I−V characteristics. Inset is the AFM to identify the thickness of the film. Suspension of exfoliated graphene in ethanol was spin coated over quartz to obtain the film. (h) Cyclic voltammetry curves of the graphene at different scan rates. (i) Galvanostatic charge−discharge curves at different current densities. So, if the plasma gas velocity can further be increased by increasing the primary gas flow rate from 120 to 140 SCFH, ideally it should have efficient exfoliation having a greater number of single layers. However, it is to be noted that increasing the gas flow rate will cause the drop in in-flight particle temperature (3430 °C at P7G3, 3300 °C at P7G4) and the phenomena of thermal shock may be disturbed. To confirm our findings, we varied the process parameters from P7G3 (T: 3430 °C, V: 350 m/s) to P5G3 (T: 3280 °C, V: 323 m/s), and TEM analysis of the exfoliated graphene showed the presence of multilayer instead of 1−3 layers (Supporting Information S16). This has further verified our findings that the right combination of temperature and velocity will have an impact on the number of layers of graphene. With the more rigorous trials, the process sheets can further be designed to achieve the exact dependency of process parameters on the exfoliation of graphitic layers. For commercial production of graphene, two of the most critical metrics are the yield and production rate. These metrics to some point have suffered from the lack of standardization. As an example, past studies simply divided the mass of exfoliated graphene by mass of original graphite to obtain yield without considering additional separation steps, which reduce yield.17,42 Henceforth, studies overestimate yields up to 93% of the total parent mass under optimal conditions. Here, we define our yield as the product obtained after exfoliation and mild centrifugation. Note that our process does not require extensive cleaning of the collected supernatant such as solvent removal that reduces yield. Our laboratory-scale experiments result in yield up to 40% comparable with other exfoliation techniques (refer to Supporting Information S17 for more detailed information on yield). Additionally, we define our graphene production rate which is one of the most critical aspects to prototype industrialization. Our prototype lab-scale experiments demonstrated graphene production rate over 48 g/h. Additionally, it cost us around USD $1.12 to produce 1 g of graphene (Supporting Information S18). It is to be noted that production cost depends upon the local condition (i.e., https://dx.doi.org/10.1021/acsnano.0c09451 1781 ACS Nano 2021, 15, 1775−1784PDF Image | Production of High Quality Exfoliated Graphene

PDF Search Title:

Production of High Quality Exfoliated GrapheneOriginal File Name Searched:

Ultra-Fast-Chemical-Exfoliated-Graphene.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |