PDF Publication Title:

Text from PDF Page: 228

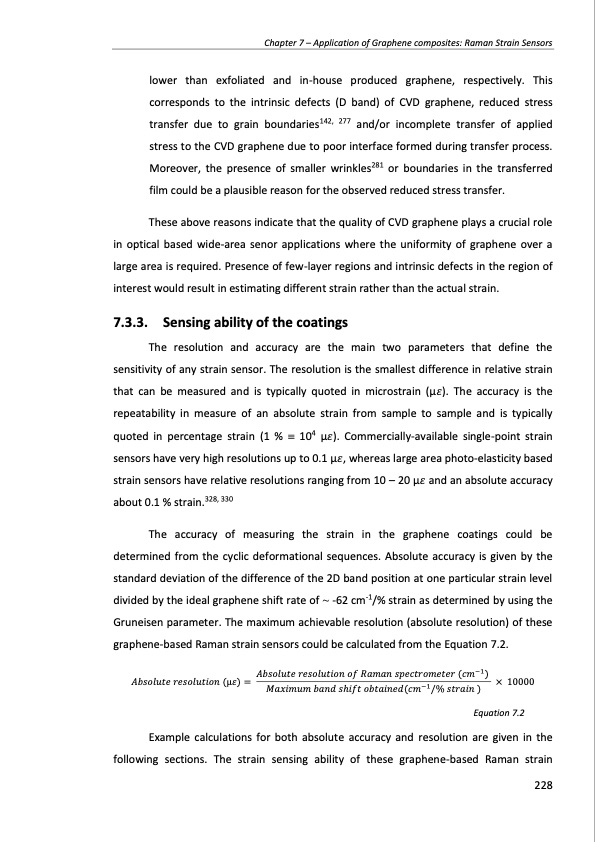

Chapter 7 – Application of Graphene composites: Raman Strain Sensors lower than exfoliated and in-house produced graphene, respectively. This corresponds to the intrinsic defects (D band) of CVD graphene, reduced stress transfer due to grain boundaries142, 277 and/or incomplete transfer of applied stress to the CVD graphene due to poor interface formed during transfer process. Moreover, the presence of smaller wrinkles281 or boundaries in the transferred film could be a plausible reason for the observed reduced stress transfer. These above reasons indicate that the quality of CVD graphene plays a crucial role in optical based wide-area senor applications where the uniformity of graphene over a large area is required. Presence of few-layer regions and intrinsic defects in the region of interest would result in estimating different strain rather than the actual strain. 7.3.3. Sensing ability of the coatings The resolution and accuracy are the main two parameters that define the sensitivity of any strain sensor. The resolution is the smallest difference in relative strain that can be measured and is typically quoted in microstrain (μ𝜀). The accuracy is the repeatability in measure of an absolute strain from sample to sample and is typically quoted in percentage strain (1 % 104 μ𝜀). Commercially-available single-point strain sensors have very high resolutions up to 0.1 μ𝜀, whereas large area photo-elasticity based strain sensors have relative resolutions ranging from 10 – 20 μ𝜀 and an absolute accuracy about 0.1 % strain.328, 330 The accuracy of measuring the strain in the graphene coatings could be determined from the cyclic deformational sequences. Absolute accuracy is given by the standard deviation of the difference of the 2D band position at one particular strain level divided by the ideal graphene shift rate of ~ -62 cm-1/% strain as determined by using the Gruneisen parameter. The maximum achievable resolution (absolute resolution) of these graphene-based Raman strain sensors could be calculated from the Equation 7.2. 𝐴𝑏𝑠𝑜𝑙𝑢𝑡𝑒 𝑟𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (μ𝜀) = 𝐴𝑏𝑠𝑜𝑙𝑢𝑡𝑒 𝑟𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑜𝑓 𝑅𝑎𝑚𝑎𝑛 𝑠𝑝𝑒𝑐𝑡𝑟𝑜𝑚𝑒𝑡𝑒𝑟 (𝑐𝑚−1) × 10000 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝑏𝑎𝑛𝑑 𝑠h𝑖𝑓𝑡 𝑜𝑏𝑡𝑎𝑖𝑛𝑒𝑑(𝑐𝑚−1/% 𝑠𝑡𝑟𝑎𝑖𝑛 ) Equation 7.2 Example calculations for both absolute accuracy and resolution are given in the following sections. The strain sensing ability of these graphene-based Raman strain 228PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)