PDF Publication Title:

Text from PDF Page: 210

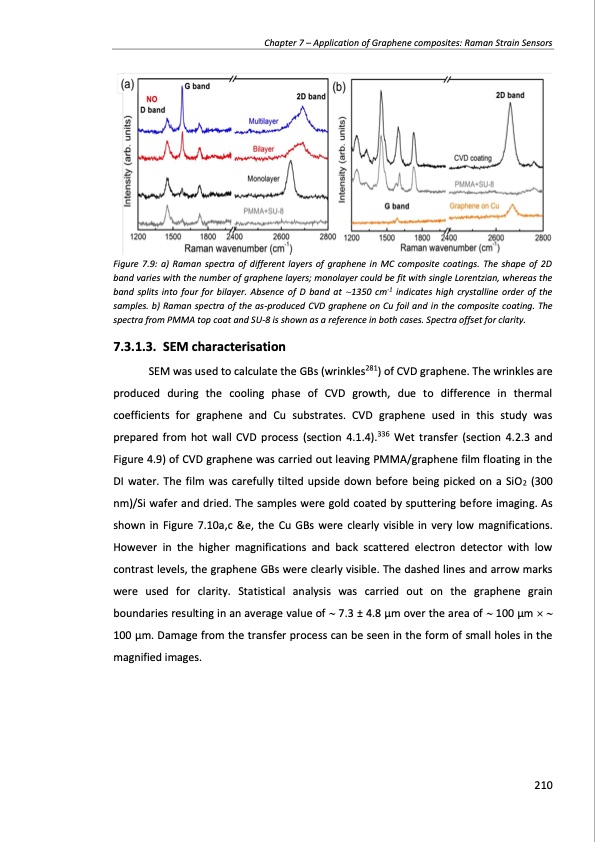

Chapter 7 – Application of Graphene composites: Raman Strain Sensors Figure 7.9: a) Raman spectra of different layers of graphene in MC composite coatings. The shape of 2D band varies with the number of graphene layers; monolayer could be fit with single Lorentzian, whereas the band splits into four for bilayer. Absence of D band at ~1350 cm-1 indicates high crystalline order of the samples. b) Raman spectra of the as-produced CVD graphene on Cu foil and in the composite coating. The spectra from PMMA top coat and SU-8 is shown as a reference in both cases. Spectra offset for clarity. 7.3.1.3. SEM characterisation SEM was used to calculate the GBs (wrinkles281) of CVD graphene. The wrinkles are produced during the cooling phase of CVD growth, due to difference in thermal coefficients for graphene and Cu substrates. CVD graphene used in this study was prepared from hot wall CVD process (section 4.1.4).336 Wet transfer (section 4.2.3 and Figure 4.9) of CVD graphene was carried out leaving PMMA/graphene film floating in the DI water. The film was carefully tilted upside down before being picked on a SiO2 (300 nm)/Si wafer and dried. The samples were gold coated by sputtering before imaging. As shown in Figure 7.10a,c &e, the Cu GBs were clearly visible in very low magnifications. However in the higher magnifications and back scattered electron detector with low contrast levels, the graphene GBs were clearly visible. The dashed lines and arrow marks were used for clarity. Statistical analysis was carried out on the graphene grain boundaries resulting in an average value of 7.3 ± 4.8 μm over the area of 100 μm 100 μm. Damage from the transfer process can be seen in the form of small holes in the magnified images. 210PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |