PDF Publication Title:

Text from PDF Page: 204

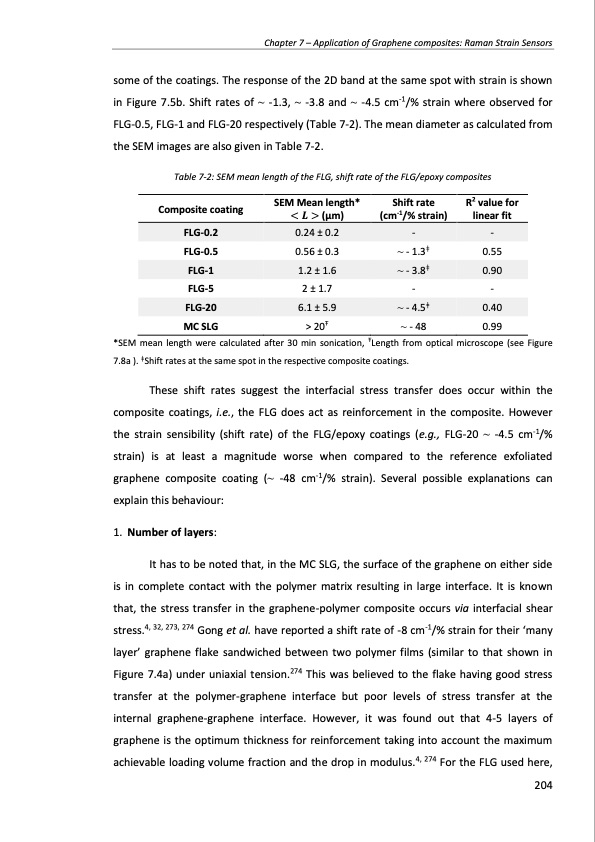

Chapter 7 – Application of Graphene composites: Raman Strain Sensors some of the coatings. The response of the 2D band at the same spot with strain is shown in Figure 7.5b. Shift rates of ~ -1.3, ~ -3.8 and ~ -4.5 cm-1/% strain where observed for FLG-0.5, FLG-1 and FLG-20 respectively (Table 7-2). The mean diameter as calculated from the SEM images are also given in Table 7-2. Table 7-2: SEM mean length of the FLG, shift rate of the FLG/epoxy composites R2 value for linear fit 0.55 - 0.99 These shift rates suggest the interfacial stress transfer does occur within the composite coatings, i.e., the FLG does act as reinforcement in the composite. However the strain sensibility (shift rate) of the FLG/epoxy coatings (e.g., FLG-20 ~ -4.5 cm-1/% strain) is at least a magnitude worse when compared to the reference exfoliated graphene composite coating (~ -48 cm-1/% strain). Several possible explanations can explain this behaviour: 1. Number of layers: It has to be noted that, in the MC SLG, the surface of the graphene on either side is in complete contact with the polymer matrix resulting in large interface. It is known that, the stress transfer in the graphene-polymer composite occurs via interfacial shear stress.4, 32, 273, 274 Gong et al. have reported a shift rate of -8 cm-1/% strain for their ‘many layer’ graphene flake sandwiched between two polymer films (similar to that shown in Figure 7.4a) under uniaxial tension.274 This was believed to the flake having good stress transfer at the polymer-graphene interface but poor levels of stress transfer at the internal graphene-graphene interface. However, it was found out that 4-5 layers of graphene is the optimum thickness for reinforcement taking into account the maximum achievable loading volume fraction and the drop in modulus.4, 274 For the FLG used here, Composite coating FLG-0.5 FLG-5 SEM Mean length* < 𝑳 > (μm) 0.56 ± 0.3 2 ± 1.7 > 20Ŧ Shift rate (cm-1/% strain) ~ - 1.3ǂ - FLG-0.2 0.24 ± 0.2 - - FLG-1 1.2 ± 1.6 ~ - 3.8ǂ 0.90 FLG-20 6.1 ± 5.9 ~ - 4.5ǂ 0.40 ~ - 48 *SEM mean length were calculated after 30 min sonication, ŦLength from optical microscope (see Figure MC SLG 7.8a ). ǂShift rates at the same spot in the respective composite coatings. 204PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |