PDF Publication Title:

Text from PDF Page: 152

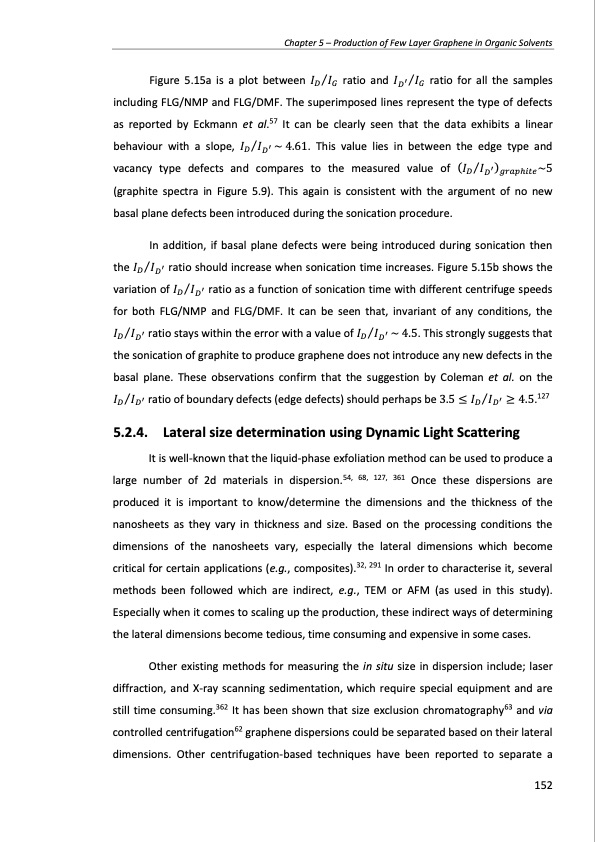

Chapter 5 – Production of Few Layer Graphene in Organic Solvents Figure 5.15a is a plot between 𝐼𝐷⁄𝐼𝐺 ratio and 𝐼𝐷′⁄𝐼𝐺 ratio for all the samples including FLG/NMP and FLG/DMF. The superimposed lines represent the type of defects as reported by Eckmann et al.57 It can be clearly seen that the data exhibits a linear behaviour with a slope, 𝐼𝐷⁄𝐼𝐷′ ~ 4.61. This value lies in between the edge type and vacancy type defects and compares to the measured value of (𝐼𝐷 ⁄𝐼𝐷′ )𝑔𝑟𝑎𝑝h𝑖𝑡𝑒 ~5 (graphite spectra in Figure 5.9). This again is consistent with the argument of no new basal plane defects been introduced during the sonication procedure. In addition, if basal plane defects were being introduced during sonication then the 𝐼𝐷⁄𝐼𝐷′ ratio should increase when sonication time increases. Figure 5.15b shows the variation of 𝐼𝐷⁄𝐼𝐷′ ratio as a function of sonication time with different centrifuge speeds for both FLG/NMP and FLG/DMF. It can be seen that, invariant of any conditions, the 𝐼𝐷⁄𝐼𝐷′ ratio stays within the error with a value of 𝐼𝐷⁄𝐼𝐷′ ~ 4.5. This strongly suggests that the sonication of graphite to produce graphene does not introduce any new defects in the basal plane. These observations confirm that the suggestion by Coleman et al. on the 𝐼𝐷⁄𝐼𝐷′ ratio of boundary defects (edge defects) should perhaps be 3.5 ≤ 𝐼𝐷⁄𝐼𝐷′ ≥ 4.5.127 5.2.4. Lateral size determination using Dynamic Light Scattering It is well-known that the liquid-phase exfoliation method can be used to produce a large number of 2d materials in dispersion.54, 68, 127, 361 Once these dispersions are produced it is important to know/determine the dimensions and the thickness of the nanosheets as they vary in thickness and size. Based on the processing conditions the dimensions of the nanosheets vary, especially the lateral dimensions which become critical for certain applications (e.g., composites).32, 291 In order to characterise it, several methods been followed which are indirect, e.g., TEM or AFM (as used in this study). Especially when it comes to scaling up the production, these indirect ways of determining the lateral dimensions become tedious, time consuming and expensive in some cases. Other existing methods for measuring the in situ size in dispersion include; laser diffraction, and X-ray scanning sedimentation, which require special equipment and are still time consuming.362 It has been shown that size exclusion chromatography63 and via controlled centrifugation62 graphene dispersions could be separated based on their lateral dimensions. Other centrifugation-based techniques have been reported to separate a 152PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |