PDF Publication Title:

Text from PDF Page: 084

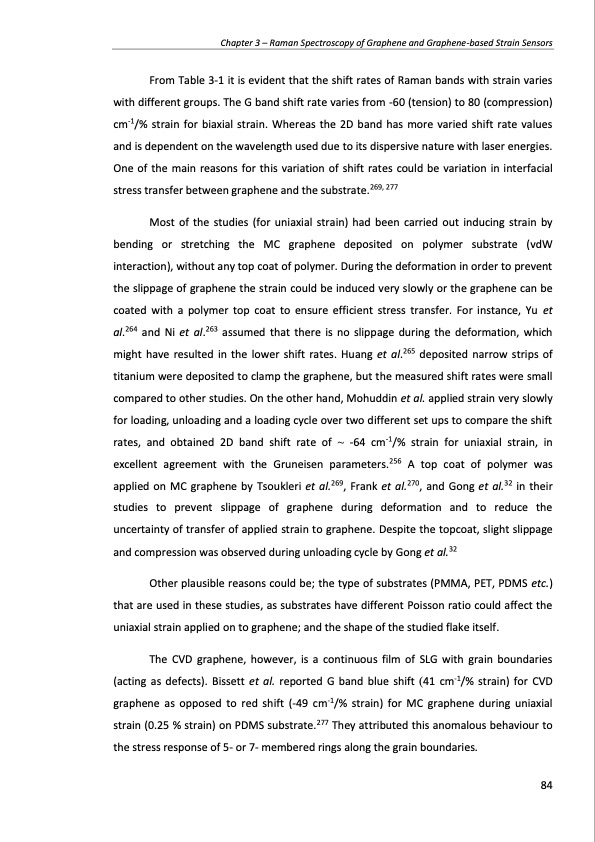

Chapter 3 – Raman Spectroscopy of Graphene and Graphene-based Strain Sensors From Table 3-1 it is evident that the shift rates of Raman bands with strain varies with different groups. The G band shift rate varies from -60 (tension) to 80 (compression) cm-1/% strain for biaxial strain. Whereas the 2D band has more varied shift rate values and is dependent on the wavelength used due to its dispersive nature with laser energies. One of the main reasons for this variation of shift rates could be variation in interfacial stress transfer between graphene and the substrate.269, 277 Most of the studies (for uniaxial strain) had been carried out inducing strain by bending or stretching the MC graphene deposited on polymer substrate (vdW interaction), without any top coat of polymer. During the deformation in order to prevent the slippage of graphene the strain could be induced very slowly or the graphene can be coated with a polymer top coat to ensure efficient stress transfer. For instance, Yu et al.264 and Ni et al.263 assumed that there is no slippage during the deformation, which might have resulted in the lower shift rates. Huang et al.265 deposited narrow strips of titanium were deposited to clamp the graphene, but the measured shift rates were small compared to other studies. On the other hand, Mohuddin et al. applied strain very slowly for loading, unloading and a loading cycle over two different set ups to compare the shift rates, and obtained 2D band shift rate of ~ -64 cm-1/% strain for uniaxial strain, in excellent agreement with the Gruneisen parameters.256 A top coat of polymer was applied on MC graphene by Tsoukleri et al.269, Frank et al.270, and Gong et al.32 in their studies to prevent slippage of graphene during deformation and to reduce the uncertainty of transfer of applied strain to graphene. Despite the topcoat, slight slippage and compression was observed during unloading cycle by Gong et al.32 Other plausible reasons could be; the type of substrates (PMMA, PET, PDMS etc.) that are used in these studies, as substrates have different Poisson ratio could affect the uniaxial strain applied on to graphene; and the shape of the studied flake itself. The CVD graphene, however, is a continuous film of SLG with grain boundaries (acting as defects). Bissett et al. reported G band blue shift (41 cm-1/% strain) for CVD graphene as opposed to red shift (-49 cm-1/% strain) for MC graphene during uniaxial strain (0.25 % strain) on PDMS substrate.277 They attributed this anomalous behaviour to the stress response of 5- or 7- membered rings along the grain boundaries. 84PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |