PDF Publication Title:

Text from PDF Page: 034

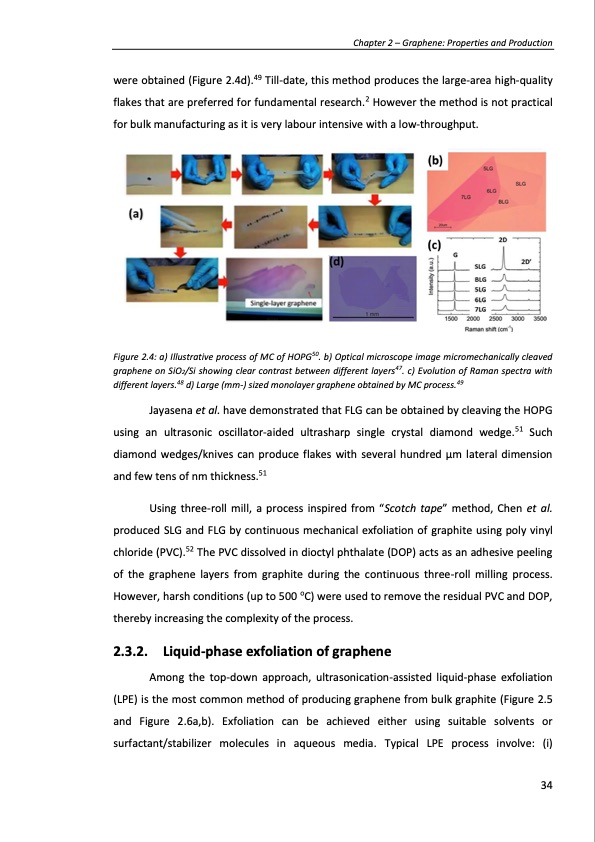

were obtained (Figure 2.4d).49 Till-date, this method produces the large-area high-quality flakes that are preferred for fundamental research.2 However the method is not practical for bulk manufacturing as it is very labour intensive with a low-throughput. Figure 2.4: a) Illustrative process of MC of HOPG50. b) Optical microscope image micromechanically cleaved graphene on SiO2/Si showing clear contrast between different layers47. c) Evolution of Raman spectra with different layers.48 d) Large (mm-) sized monolayer graphene obtained by MC process.49 Jayasena et al. have demonstrated that FLG can be obtained by cleaving the HOPG using an ultrasonic oscillator-aided ultrasharp single crystal diamond wedge.51 Such diamond wedges/knives can produce flakes with several hundred μm lateral dimension and few tens of nm thickness.51 Using three-roll mill, a process inspired from “Scotch tape” method, Chen et al. produced SLG and FLG by continuous mechanical exfoliation of graphite using poly vinyl chloride (PVC).52 The PVC dissolved in dioctyl phthalate (DOP) acts as an adhesive peeling of the graphene layers from graphite during the continuous three-roll milling process. However, harsh conditions (up to 500 oC) were used to remove the residual PVC and DOP, thereby increasing the complexity of the process. 2.3.2. Liquid-phase exfoliation of graphene Among the top-down approach, ultrasonication-assisted liquid-phase exfoliation (LPE) is the most common method of producing graphene from bulk graphite (Figure 2.5 and Figure 2.6a,b). Exfoliation can be achieved either using suitable solvents or surfactant/stabilizer molecules in aqueous media. Typical LPE process involve: (i) Chapter 2 – Graphene: Properties and Production 34PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)