PDF Publication Title:

Text from PDF Page: 003

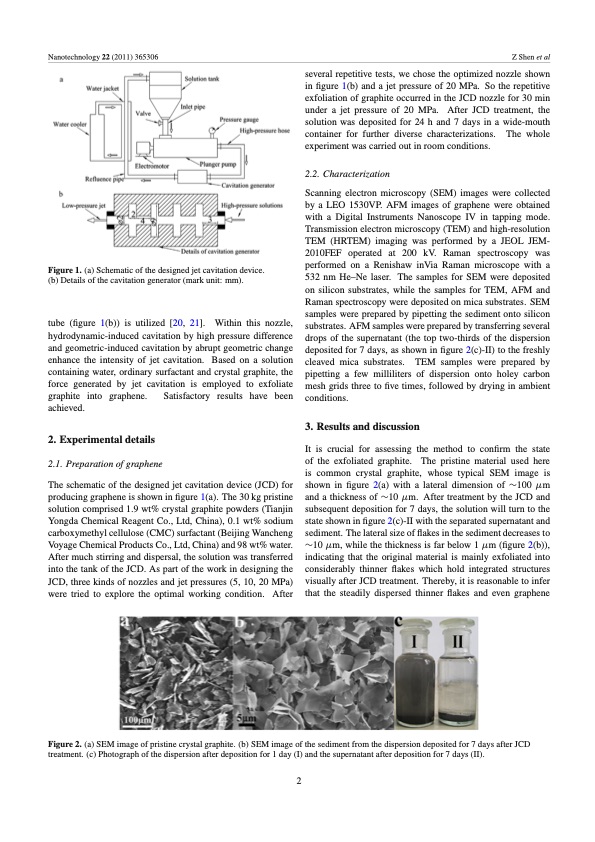

Nanotechnology 22 (2011) 365306 Z Shen et al Figure 1. (a) Schematic of the designed jet cavitation device. (b) Details of the cavitation generator (mark unit: mm). tube (figure 1(b)) is utilized [20, 21]. Within this nozzle, hydrodynamic-induced cavitation by high pressure difference and geometric-induced cavitation by abrupt geometric change enhance the intensity of jet cavitation. Based on a solution containing water, ordinary surfactant and crystal graphite, the force generated by jet cavitation is employed to exfoliate several repetitive tests, we chose the optimized nozzle shown in figure 1(b) and a jet pressure of 20 MPa. So the repetitive exfoliation of graphite occurred in the JCD nozzle for 30 min under a jet pressure of 20 MPa. After JCD treatment, the solution was deposited for 24 h and 7 days in a wide-mouth container for further diverse characterizations. The whole experiment was carried out in room conditions. 2.2. Characterization Scanning electron microscopy (SEM) images were collected by a LEO 1530VP. AFM images of graphene were obtained with a Digital Instruments Nanoscope IV in tapping mode. Transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) imaging was performed by a JEOL JEM- 2010FEF operated at 200 kV. Raman spectroscopy was performed on a Renishaw inVia Raman microscope with a 532 nm He–Ne laser. The samples for SEM were deposited on silicon substrates, while the samples for TEM, AFM and Raman spectroscopy were deposited on mica substrates. SEM samples were prepared by pipetting the sediment onto silicon substrates. AFM samples were prepared by transferring several drops of the supernatant (the top two-thirds of the dispersion deposited for 7 days, as shown in figure 2(c)-II) to the freshly cleaved mica substrates. TEM samples were prepared by pipetting a few milliliters of dispersion onto holey carbon mesh grids three to five times, followed by drying in ambient conditions. 3. Results and discussion It is crucial for assessing the method to confirm the state of the exfoliated graphite. The pristine material used here is common crystal graphite, whose typical SEM image is shown in figure 2(a) with a lateral dimension of ∼100 μm and a thickness of ∼10 μm. After treatment by the JCD and subsequent deposition for 7 days, the solution will turn to the state shown in figure 2(c)-II with the separated supernatant and sediment. The lateral size of flakes in the sediment decreases to ∼10 μm, while the thickness is far below 1 μm (figure 2(b)), indicating that the original material is mainly exfoliated into considerably thinner flakes which hold integrated structures visually after JCD treatment. Thereby, it is reasonable to infer that the steadily dispersed thinner flakes and even graphene graphite into graphene. achieved. 2. Experimental details 2.1. Preparation of graphene Satisfactory results have been The schematic of the designed jet cavitation device (JCD) for producing graphene is shown in figure 1(a). The 30 kg pristine solution comprised 1.9 wt% crystal graphite powders (Tianjin Yongda Chemical Reagent Co., Ltd, China), 0.1 wt% sodium carboxymethyl cellulose (CMC) surfactant (Beijing Wancheng Voyage Chemical Products Co., Ltd, China) and 98 wt% water. After much stirring and dispersal, the solution was transferred into the tank of the JCD. As part of the work in designing the JCD, three kinds of nozzles and jet pressures (5, 10, 20 MPa) were tried to explore the optimal working condition. After Figure 2. (a) SEM image of pristine crystal graphite. (b) SEM image of the sediment from the dispersion deposited for 7 days after JCD treatment. (c) Photograph of the dispersion after deposition for 1 day (I) and the supernatant after deposition for 7 days (II). 2PDF Image | Preparation of graphene by jet cavitation

PDF Search Title:

Preparation of graphene by jet cavitationOriginal File Name Searched:

graphene-by-jet-cavitation.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |