PDF Publication Title:

Text from PDF Page: 003

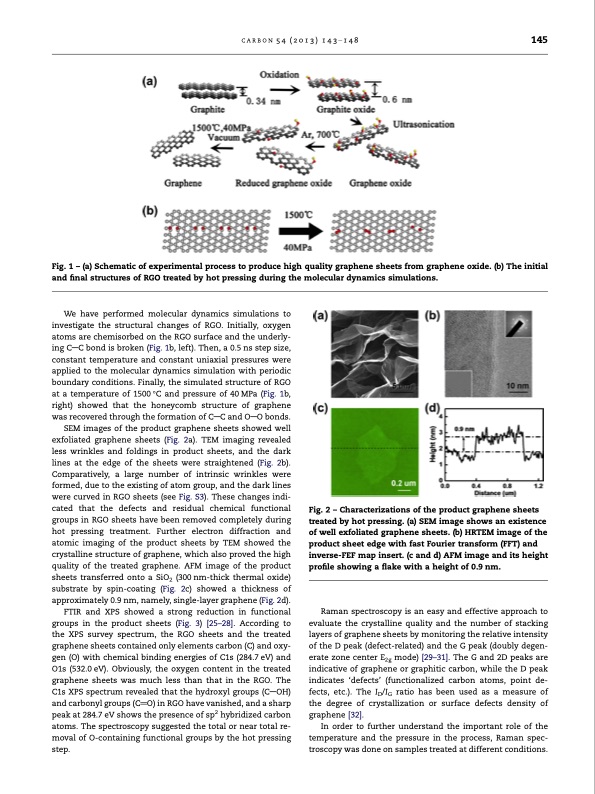

CARBON 54 (2013) 143–148 145 Fig. 1 – (a) Schematic of experimental process to produce high quality graphene sheets from graphene oxide. (b) The initial and final structures of RGO treated by hot pressing during the molecular dynamics simulations. We have performed molecular dynamics simulations to investigate the structural changes of RGO. Initially, oxygen atoms are chemisorbed on the RGO surface and the underly- ing CAC bond is broken (Fig. 1b, left). Then, a 0.5 ns step size, constant temperature and constant uniaxial pressures were applied to the molecular dynamics simulation with periodic boundary conditions. Finally, the simulated structure of RGO at a temperature of 1500 °C and pressure of 40 MPa (Fig. 1b, right) showed that the honeycomb structure of graphene was recovered through the formation of CAC and OAO bonds. SEM images of the product graphene sheets showed well exfoliated graphene sheets (Fig. 2a). TEM imaging revealed less wrinkles and foldings in product sheets, and the dark lines at the edge of the sheets were straightened (Fig. 2b). Comparatively, a large number of intrinsic wrinkles were formed, due to the existing of atom group, and the dark lines were curved in RGO sheets (see Fig. S3). These changes indi- cated that the defects and residual chemical functional groups in RGO sheets have been removed completely during hot pressing treatment. Further electron diffraction and atomic imaging of the product sheets by TEM showed the crystalline structure of graphene, which also proved the high quality of the treated graphene. AFM image of the product sheets transferred onto a SiO2 (300 nm-thick thermal oxide) substrate by spin-coating (Fig. 2c) showed a thickness of approximately 0.9 nm, namely, single-layer graphene (Fig. 2d). FTIR and XPS showed a strong reduction in functional groups in the product sheets (Fig. 3) [25–28]. According to the XPS survey spectrum, the RGO sheets and the treated graphene sheets contained only elements carbon (C) and oxy- gen (O) with chemical binding energies of C1s (284.7 eV) and O1s (532.0 eV). Obviously, the oxygen content in the treated graphene sheets was much less than that in the RGO. The C1s XPS spectrum revealed that the hydroxyl groups (CAOH) and carbonyl groups (C@O) in RGO have vanished, and a sharp peak at 284.7 eV shows the presence of sp2 hybridized carbon atoms. The spectroscopy suggested the total or near total re- moval of O-containing functional groups by the hot pressing step. Raman spectroscopy is an easy and effective approach to evaluate the crystalline quality and the number of stacking layers of graphene sheets by monitoring the relative intensity of the D peak (defect-related) and the G peak (doubly degen- erate zone center E2g mode) [29–31]. The G and 2D peaks are indicative of graphene or graphitic carbon, while the D peak indicates ‘defects’ (functionalized carbon atoms, point de- fects, etc.). The ID/IG ratio has been used as a measure of the degree of crystallization or surface defects density of graphene [32]. In order to further understand the important role of the temperature and the pressure in the process, Raman spec- troscopy was done on samples treated at different conditions. Fig. 2 – Characterizations of the product graphene sheets treated by hot pressing. (a) SEM image shows an existence of well exfoliated graphene sheets. (b) HRTEM image of the product sheet edge with fast Fourier transform (FFT) and inverse-FEF map insert. (c and d) AFM image and its height profile showing a flake with a height of 0.9 nm.PDF Image | graphene sheets from graphene oxide by hot-pressing

PDF Search Title:

graphene sheets from graphene oxide by hot-pressingOriginal File Name Searched:

345.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |