PDF Publication Title:

Text from PDF Page: 003

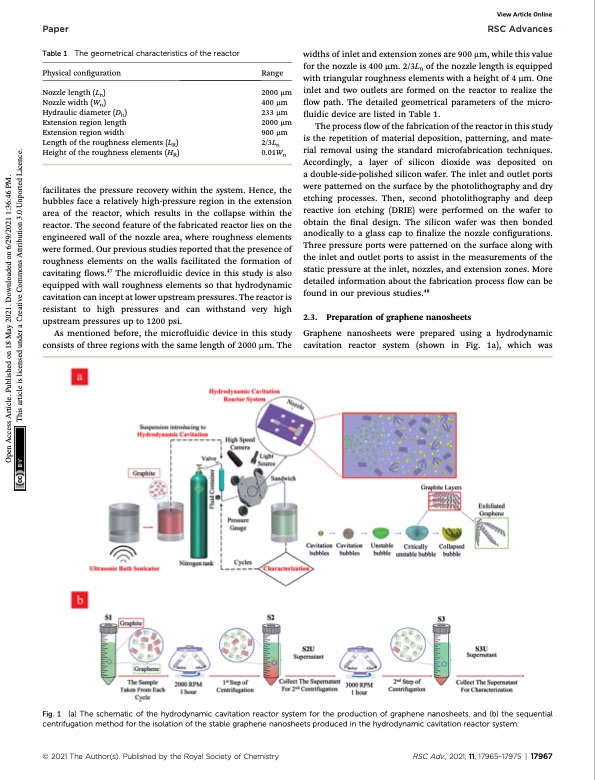

Paper RSC Advances widths of inlet and extension zones are 900 mm, while this value for the nozzle is 400 mm. 2/3Ln of the nozzle length is equipped with triangular roughness elements with a height of 4 mm. One inlet and two outlets are formed on the reactor to realize the ow path. The detailed geometrical parameters of the micro- uidic device are listed in Table 1. The process ow of the fabrication of the reactor in this study is the repetition of material deposition, patterning, and mate- rial removal using the standard microfabrication techniques. Accordingly, a layer of silicon dioxide was deposited on a double-side-polished silicon wafer. The inlet and outlet ports were patterned on the surface by the photolithography and dry etching processes. Then, second photolithography and deep reactive ion etching (DRIE) were performed on the wafer to obtain the nal design. The silicon wafer was then bonded anodically to a glass cap to nalize the nozzle congurations. Three pressure ports were patterned on the surface along with the inlet and outlet ports to assist in the measurements of the static pressure at the inlet, nozzles, and extension zones. More detailed information about the fabrication process ow can be found in our previous studies.48 2.3. Preparation of graphene nanosheets Graphene nanosheets were prepared using a hydrodynamic cavitation reactor system (shown in Fig. 1a), which was Table 1 The geometrical characteristics of the reactor Physical conguration Nozzle length (Ln) Nozzle width (Wn) Hydraulic diameter (Dh) Extension region length Extension region width Length of the roughness elements (LR) Height of the roughness elements (HR) Range 2000 mm 400 mm 233 mm 2000 mm 900 mm 2/3Ln 0.01Wn facilitates the pressure recovery within the system. Hence, the bubbles face a relatively high-pressure region in the extension area of the reactor, which results in the collapse within the reactor. The second feature of the fabricated reactor lies on the engineered wall of the nozzle area, where roughness elements were formed. Our previous studies reported that the presence of roughness elements on the walls facilitated the formation of cavitating ows.47 The microuidic device in this study is also equipped with wall roughness elements so that hydrodynamic cavitation can incept at lower upstream pressures. The reactor is resistant to high pressures and can withstand very high upstream pressures up to 1200 psi. As mentioned before, the microuidic device in this study consists of three regions with the same length of 2000 mm. The Fig. 1 (a) The schematic of the hydrodynamic cavitation reactor system for the production of graphene nanosheets, and (b) the sequential centrifugation method for the isolation of the stable graphene nanosheets produced in the hydrodynamic cavitation reactor system. © 2021 The Author(s). Published by the Royal Society of Chemistry RSC Adv., 2021, 11, 17965–17975 | 17967 View Article Online Open Access Article. Published on 18 May 2021. Downloaded on 6/29/2021 1:36:46 PM. This article is licensed under a Creative Commons Attribution 3.0 Unported Licence.PDF Image | graphene exfoliation hydrodynamic cavitation on a chip

PDF Search Title:

graphene exfoliation hydrodynamic cavitation on a chipOriginal File Name Searched:

graphene-by-cavitation.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |