PDF Publication Title:

Text from PDF Page: 002

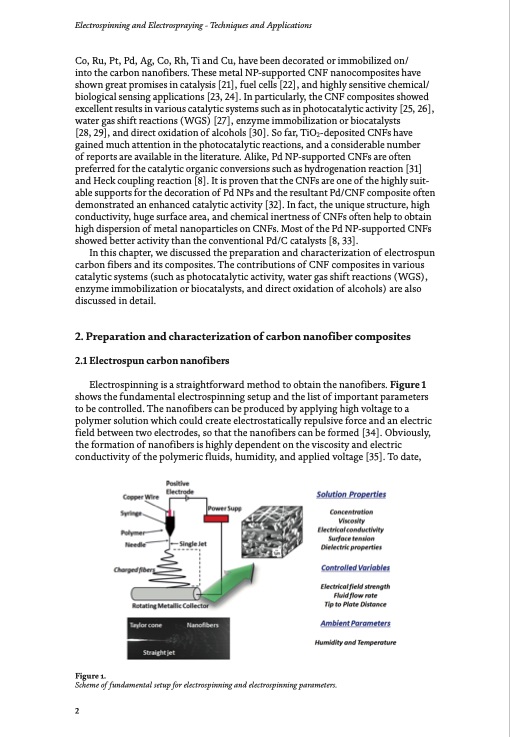

Electrospinning and Electrospraying - Techniques and Applications Co, Ru, Pt, Pd, Ag, Co, Rh, Ti and Cu, have been decorated or immobilized on/ into the carbon nanofibers. These metal NP-supported CNF nanocomposites have shown great promises in catalysis [21], fuel cells [22], and highly sensitive chemical/ biological sensing applications [23, 24]. In particularly, the CNF composites showed excellent results in various catalytic systems such as in photocatalytic activity [25, 26], water gas shift reactions (WGS) [27], enzyme immobilization or biocatalysts [28, 29], and direct oxidation of alcohols [30]. So far, TiO2-deposited CNFs have gained much attention in the photocatalytic reactions, and a considerable number of reports are available in the literature. Alike, Pd NP-supported CNFs are often preferred for the catalytic organic conversions such as hydrogenation reaction [31] and Heck coupling reaction [8]. It is proven that the CNFs are one of the highly suit- able supports for the decoration of Pd NPs and the resultant Pd/CNF composite often demonstrated an enhanced catalytic activity [32]. In fact, the unique structure, high conductivity, huge surface area, and chemical inertness of CNFs often help to obtain high dispersion of metal nanoparticles on CNFs. Most of the Pd NP-supported CNFs showed better activity than the conventional Pd/C catalysts [8, 33]. In this chapter, we discussed the preparation and characterization of electrospun carbon fibers and its composites. The contributions of CNF composites in various catalytic systems (such as photocatalytic activity, water gas shift reactions (WGS), enzyme immobilization or biocatalysts, and direct oxidation of alcohols) are also discussed in detail. 2. Preparation and characterization of carbon nanofiber composites 2.1 Electrospun carbon nanofibers Electrospinning is a straightforward method to obtain the nanofibers. Figure 1 shows the fundamental electrospinning setup and the list of important parameters to be controlled. The nanofibers can be produced by applying high voltage to a polymer solution which could create electrostatically repulsive force and an electric field between two electrodes, so that the nanofibers can be formed [34]. Obviously, the formation of nanofibers is highly dependent on the viscosity and electric conductivity of the polymeric fluids, humidity, and applied voltage [35]. To date, Figure 1. Scheme of fundamental setup for electrospinning and electrospinning parameters. 2PDF Image | Preparation, Characterization, and Applications of Electrospun Carbon Nanofibers

PDF Search Title:

Preparation, Characterization, and Applications of Electrospun Carbon NanofibersOriginal File Name Searched:

68337.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |