PDF Publication Title:

Text from PDF Page: 002

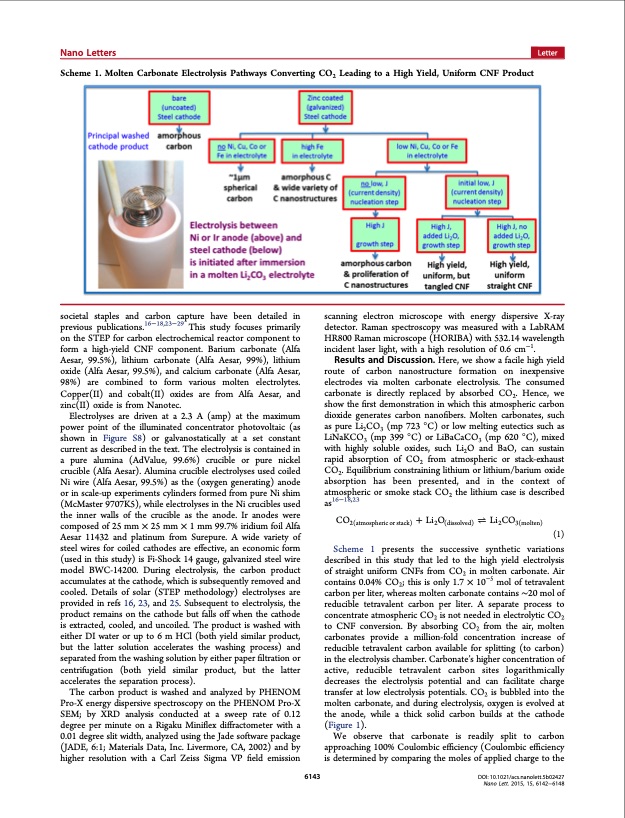

Nano Letters Letter Scheme 1. Molten Carbonate Electrolysis Pathways Converting CO2 Leading to a High Yield, Uniform CNF Product societal staples and carbon capture have been detailed in previous publications.16−18,23−29 This study focuses primarily on the STEP for carbon electrochemical reactor component to form a high-yield CNF component. Barium carbonate (Alfa Aesar, 99.5%), lithium carbonate (Alfa Aesar, 99%), lithium oxide (Alfa Aesar, 99.5%), and calcium carbonate (Alfa Aesar, 98%) are combined to form various molten electrolytes. Copper(II) and cobalt(II) oxides are from Alfa Aesar, and zinc(II) oxide is from Nanotec. Electrolyses are driven at a 2.3 A (amp) at the maximum power point of the illuminated concentrator photovoltaic (as shown in Figure S8) or galvanostatically at a set constant current as described in the text. The electrolysis is contained in a pure alumina (AdValue, 99.6%) crucible or pure nickel crucible (Alfa Aesar). Alumina crucible electrolyses used coiled Ni wire (Alfa Aesar, 99.5%) as the (oxygen generating) anode or in scale-up experiments cylinders formed from pure Ni shim (McMaster 9707K5), while electrolyses in the Ni crucibles used the inner walls of the crucible as the anode. Ir anodes were composed of 25 mm × 25 mm × 1 mm 99.7% iridium foil Alfa Aesar 11432 and platinum from Surepure. A wide variety of steel wires for coiled cathodes are effective, an economic form (used in this study) is Fi-Shock 14 gauge, galvanized steel wire model BWC-14200. During electrolysis, the carbon product accumulates at the cathode, which is subsequently removed and cooled. Details of solar (STEP methodology) electrolyses are provided in refs 16, 23, and 25. Subsequent to electrolysis, the product remains on the cathode but falls off when the cathode is extracted, cooled, and uncoiled. The product is washed with either DI water or up to 6 m HCl (both yield similar product, but the latter solution accelerates the washing process) and separated from the washing solution by either paper filtration or centrifugation (both yield similar product, but the latter accelerates the separation process). The carbon product is washed and analyzed by PHENOM Pro-X energy dispersive spectroscopy on the PHENOM Pro-X SEM; by XRD analysis conducted at a sweep rate of 0.12 degree per minute on a Rigaku Miniflex diffractometer with a 0.01 degree slit width, analyzed using the Jade software package (JADE, 6:1; Materials Data, Inc. Livermore, CA, 2002) and by higher resolution with a Carl Zeiss Sigma VP field emission 6143 scanning electron microscope with energy dispersive X-ray detector. Raman spectroscopy was measured with a LabRAM HR800 Raman microscope (HORIBA) with 532.14 wavelength incident laser light, with a high resolution of 0.6 cm−1. Results and Discussion. Here, we show a facile high yield route of carbon nanostructure formation on inexpensive electrodes via molten carbonate electrolysis. The consumed carbonate is directly replaced by absorbed CO2. Hence, we show the first demonstration in which this atmospheric carbon dioxide generates carbon nanofibers. Molten carbonates, such as pure Li2CO3 (mp 723 °C) or low melting eutectics such as LiNaKCO3 (mp 399 °C) or LiBaCaCO3 (mp 620 °C), mixed with highly soluble oxides, such Li2O and BaO, can sustain rapid absorption of CO2 from atmospheric or stack-exhaust CO2. Equilibrium constraining lithium or lithium/barium oxide absorption has been presented, and in the context of atmospheric or smoke stack CO2 the lithium case is described as16−18,23 CO2(atmospheric or stack) + Li2O(dissolved) ⇌ Li2CO3(molten) (1) Scheme 1 presents the successive synthetic variations described in this study that led to the high yield electrolysis of straight uniform CNFs from CO2 in molten carbonate. Air contains 0.04% CO2; this is only 1.7 × 10−5 mol of tetravalent carbon per liter, whereas molten carbonate contains ∼20 mol of reducible tetravalent carbon per liter. A separate process to concentrate atmospheric CO2 is not needed in electrolytic CO2 to CNF conversion. By absorbing CO2 from the air, molten carbonates provide a million-fold concentration increase of reducible tetravalent carbon available for splitting (to carbon) in the electrolysis chamber. Carbonate’s higher concentration of active, reducible tetravalent carbon sites logarithmically decreases the electrolysis potential and can facilitate charge transfer at low electrolysis potentials. CO2 is bubbled into the molten carbonate, and during electrolysis, oxygen is evolved at the anode, while a thick solid carbon builds at the cathode (Figure 1). We observe that carbonate is readily split to carbon approaching 100% Coulombic efficiency (Coulombic efficiency is determined by comparing the moles of applied charge to the DOI: 10.1021/acs.nanolett.5b02427 Nano Lett. 2015, 15, 6142−6148PDF Image | One-Pot Synthesis of Carbon Nanofibers from CO2

PDF Search Title:

One-Pot Synthesis of Carbon Nanofibers from CO2Original File Name Searched:

acs.nanolett.5b02427.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |