PDF Publication Title:

Text from PDF Page: 003

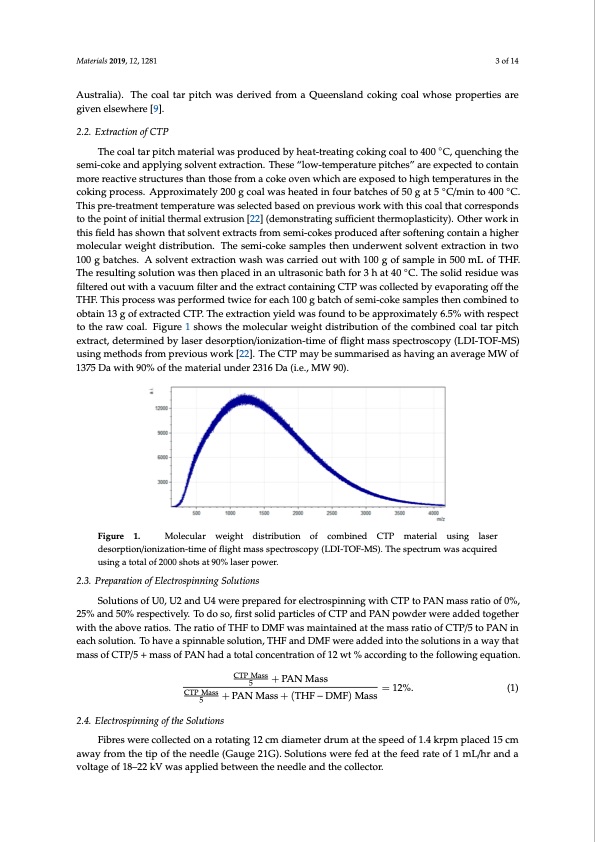

Materials 2019, 12, 1281 3 of 14 Materials 2019, 12, x FOR PEER REVIEW 3 of 14 Australia). The coal tar pitch was derived from a Queensland coking coal whose properties are (Sydney, Australia). The coal tar pitch was derived from a Queensland coking coal whose properties given elsewhere [9]. are given elsewhere [9]. 2.2. Extraction of CTP 2.2. Extraction of CTP The coal tar pitch material was produced by heat-treating coking coal to 400 ◦C, quenching the The coal tar pitch material was produced by heat-treating coking coal to 400 °C, quenching the semi-coke and applying solvent extraction. These “low-temperature pitches” are expected to contain semi-coke and applying solvent extraction. These “low-temperature pitches” are expected to contain more reactive structures than those from a coke oven which are exposed to high temperatures in the more reactive structures than those from a coke oven which are exposed to high temperatures in the coking process. Approximately 200 g coal was heated in four batches of 50 g at 5 ◦C/min to 400 ◦C. coking process. Approximately 200 g coal was heated in four batches of 50 g at 5 °C/min to 400 °C. This pre-treatment temperature was selected based on previous work with this coal that corresponds This pre-treatment temperature was selected based on previous work with this coal that corresponds to the point of initial thermal extrusion [22] (demonstrating sufficient thermoplasticity). Other work in to the point of initial thermal extrusion [22] (demonstrating sufficient thermoplasticity). Other work this field has shown that solvent extracts from semi-cokes produced after softening contain a higher in this field has shown that solvent extracts from semi-cokes produced after softening contain a molecular weight distribution. The semi-coke samples then underwent solvent extraction in two higher molecular weight distribution. The semi-coke samples then underwent solvent extraction in 100 g batches. A solvent extraction wash was carried out with 100 g of sample in 500 mL of THF. two 100 g batches. A solvent extraction wash was carried out with 100 g of sample in 500 mL of THF. The resulting solution was then placed in an ultrasonic bath for 3 h at 40 ◦C. The solid residue was The resulting solution was then placed in an ultrasonic bath for 3 h at 40 °C. The solid residue was filtered out with a vacuum filter and the extract containing CTP was collected by evaporating off the filtered out with a vacuum filter and the extract containing CTP was collected by evaporating off the THF. This process was performed twice for each 100 g batch of semi-coke samples then combined to THF. This process was performed twice for each 100 g batch of semi-coke samples then combined to obtain 13 g of extracted CTP. The extraction yield was found to be approximately 6.5% with respect obtain 13 g of extracted CTP. The extraction yield was found to be approximately 6.5% with respect to the raw coal. Figure 1 shows the molecular weight distribution of the combined coal tar pitch to the raw coal. Figure 1 shows the molecular weight distribution of the combined coal tar pitch extract, determined by laser desorption/ionization-time of flight mass spectroscopy (LDI-TOF-MS) extract, determined by laser desorption/ionization-time of flight mass spectroscopy (LDI-TOF-MS) using methods from previous work [22]. The CTP may be summarised as having an average MW of using methods from previous work [22]. The CTP may be summarised as having an average MW of 1375 Da with 90% of the material under 2316 Da (i.e., MW 90). 1375 Da with 90% of the material under 2316 Da (i.e., MW 90). Figure 1. Molecular weight distribution of combined CTP material using laser Figure 1. Molecular weight distribution of combined CTP material using laser desorption/ionization- desorption/ionization-time of flight mass spectroscopy (LDI-TOF-MS). The spectrum was acquired time of flight mass spectroscopy (LDI-TOF-MS). The spectrum was acquired using a total of 2000 using a total of 2000 shots at 90% laser power. shots at 90% laser power. 2.3. Preparation of Electrospinning Solutions 2.3. Preparation of Electrospinning Solutions Solutions of U0, U2 and U4 were prepared for electrospinning with CTP to PAN mass ratio of 0%, Solutions of U0, U2 and U4 were prepared for electrospinning with CTP to PAN mass ratio of 25% and 50% respectively. To do so, first solid particles of CTP and PAN powder were added together 0%, 25% and 50% respectively. To do so, first solid particles of CTP and PAN powder were added with the above ratios. The ratio of THF to DMF was maintained at the mass ratio of CTP/5 to PAN in together with the above ratios. The ratio of THF to DMF was maintained at the mass ratio of CTP/5 each solution. To have a spinnable solution, THF and DMF were added into the solutions in a way that to PAN in each solution. To have a spinnable solution, THF and DMF were added into the solutions mass of CTP/5 + mass of PAN had a total concentration of 12 wt % according to the following equation. in a way that mass of CTP/5 + mass of PAN had a total concentration of 12 wt % according to the following equation. CTP Mass + PAN Mass 5 2.4. Electrospinning of the Solutions 2.4. Electrospinning of the Solutions CTP Mass 5 = 12%. (1) = 12%. (1) +PANMass+(THF− DMF)Mass (-) Fibres were collected on a rotating 12 cm diameter drum at the speed of 1.4 krpm placed 15 cm away from the tip of the needle (Gauge 21G). Solutions were fed at the feed rate of 1 mL/hr and a Fibres were collected on a rotating 12 cm diameter drum at the speed of 1.4 krpm placed 15 cm voltage of 18–22 kV was applied between the needle and the collector. away from the tip of the needle (Gauge 21G). Solutions were fed at the feed rate of 1 mL/hr and a voltage of 18–22 kV was applied between the needle and the collector.PDF Image | Low-Cost Carbon Fibre Derived from Sustainable Coal Tar Pitch and Polyacrylonitrile

PDF Search Title:

Low-Cost Carbon Fibre Derived from Sustainable Coal Tar Pitch and PolyacrylonitrileOriginal File Name Searched:

6e63fb65b81e089e97ddfbe19bee7d22311e.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |