PDF Publication Title:

Text from PDF Page: 003

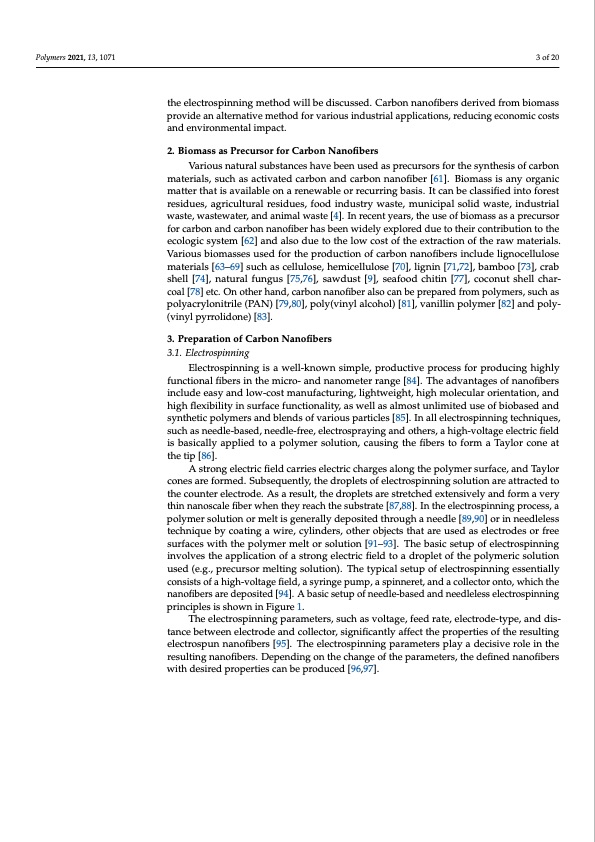

Polymers 2021, 13, 1071 3 of 20 the electrospinning method will be discussed. Carbon nanofibers derived from biomass provide an alternative method for various industrial applications, reducing economic costs and environmental impact. 2. Biomass as Precursor for Carbon Nanofibers Various natural substances have been used as precursors for the synthesis of carbon materials, such as activated carbon and carbon nanofiber [61]. Biomass is any organic matter that is available on a renewable or recurring basis. It can be classified into forest residues, agricultural residues, food industry waste, municipal solid waste, industrial waste, wastewater, and animal waste [4]. In recent years, the use of biomass as a precursor for carbon and carbon nanofiber has been widely explored due to their contribution to the ecologic system [62] and also due to the low cost of the extraction of the raw materials. Various biomasses used for the production of carbon nanofibers include lignocellulose materials [63–69] such as cellulose, hemicellulose [70], lignin [71,72], bamboo [73], crab shell [74], natural fungus [75,76], sawdust [9], seafood chitin [77], coconut shell char- coal [78] etc. On other hand, carbon nanofiber also can be prepared from polymers, such as polyacrylonitrile (PAN) [79,80], poly(vinyl alcohol) [81], vanillin polymer [82] and poly- (vinyl pyrrolidone) [83]. 3. Preparation of Carbon Nanofibers 3.1. Electrospinning Electrospinning is a well-known simple, productive process for producing highly functional fibers in the micro- and nanometer range [84]. The advantages of nanofibers include easy and low-cost manufacturing, lightweight, high molecular orientation, and high flexibility in surface functionality, as well as almost unlimited use of biobased and synthetic polymers and blends of various particles [85]. In all electrospinning techniques, such as needle-based, needle-free, electrospraying and others, a high-voltage electric field is basically applied to a polymer solution, causing the fibers to form a Taylor cone at the tip [86]. A strong electric field carries electric charges along the polymer surface, and Taylor cones are formed. Subsequently, the droplets of electrospinning solution are attracted to the counter electrode. As a result, the droplets are stretched extensively and form a very thin nanoscale fiber when they reach the substrate [87,88]. In the electrospinning process, a polymer solution or melt is generally deposited through a needle [89,90] or in needleless technique by coating a wire, cylinders, other objects that are used as electrodes or free surfaces with the polymer melt or solution [91–93]. The basic setup of electrospinning involves the application of a strong electric field to a droplet of the polymeric solution used (e.g., precursor melting solution). The typical setup of electrospinning essentially consists of a high-voltage field, a syringe pump, a spinneret, and a collector onto, which the nanofibers are deposited [94]. A basic setup of needle-based and needleless electrospinning principles is shown in Figure 1. The electrospinning parameters, such as voltage, feed rate, electrode-type, and dis- tance between electrode and collector, significantly affect the properties of the resulting electrospun nanofibers [95]. The electrospinning parameters play a decisive role in the resulting nanofibers. Depending on the change of the parameters, the defined nanofibers with desired properties can be produced [96,97].PDF Image | Electrospun Carbon Nanofibers from Biomass and Biomass Blends

PDF Search Title:

Electrospun Carbon Nanofibers from Biomass and Biomass BlendsOriginal File Name Searched:

88145ac687f0c36c7096f236fabe2cba856c.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |